Addressable vs Conventional Fire Alarm Systems: Which Is Right for Your Building?

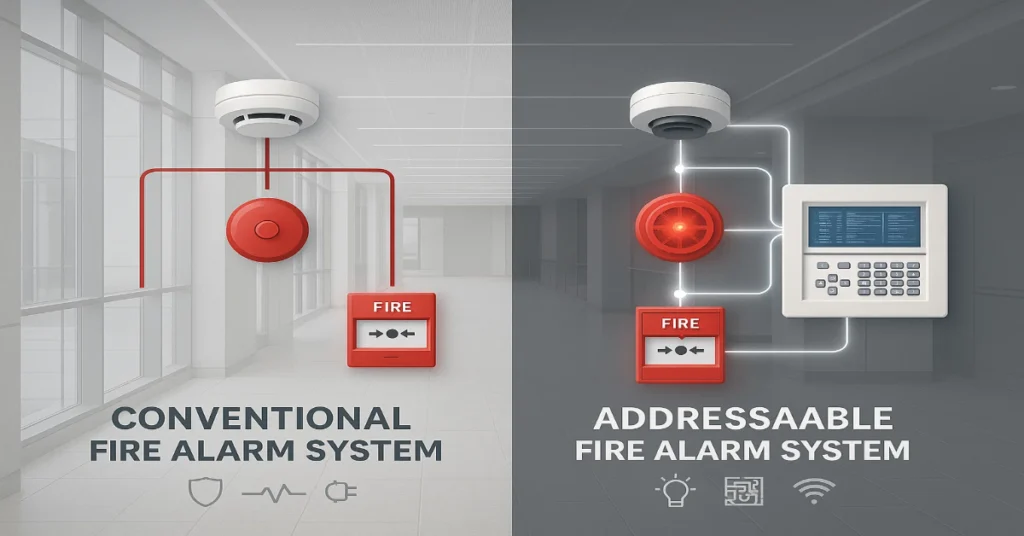

Fire alarm systems come in two basic types: conventional and addressable. In a conventional system, detectors and pull stations are wired in separate circuits or zones and the control panel simply indicates which zone has an alarm. An addressable system, by contrast, communicates with each device individually. Each detector or module has a unique address. When a sensor is triggered, the panel pinpoints the exact device and location. In practical terms, conventional panels give only zone information (e.g. “Alarm in Zone 3”), whereas addressable panels report precisely which detector went into alarm (e.g. “Smoke Detector 4.23 – Warehouse, Aisle 3”). This guide on addressable vs conventional fire alarm systems explains how each works, highlights their pros and cons and helps industrial managers choose the right solution for their facility. Conventional vs Addressable Fire Alarm Systems: Working Feature Conventional Fire Alarm System Addressable Fire Alarm System System Layout Building divided into zones; each zone has its own circuit wired back to the main panel. Devices wired in loops (circuits go out and return to panel). One loop can support dozens or hundreds of devices. Wiring Method All devices in a zone share the same pair of wires; requires multiple “home-run” circuits. Only two wires per loop (out and back). Less cabling overall. Device Identification Panel shows only the zone in alarm (e.g., “Zone 2 – Second Floor East Wing”). Cannot identify the exact device. Each device has a unique digital address. Panel shows the exact detector and location (e.g., “Smoke Detector 04-23 – Warehouse, Aisle 3”). Supervision Method Analog supervision with resistors to monitor voltage/current changes. Detects alarms or open circuits. Digital communication. Panel continuously polls devices and receives real-time status updates. Response Process Responders must manually search the indicated zone to locate the exact source of fire. Responders know the precise location immediately, speeding up investigation and evacuation. Fault Detection Limited to showing “trouble” if a circuit is broken or shorted. Requires manual tracing. Devices can report their own faults (e.g., dirty sensor, wiring issue). Isolation modules keep rest of system active if one section fails. Installation Effort High – extensive conduit and copper wiring required. Each device wired directly to the panel. Lower – fewer cables required. Adding devices is easier since they join the existing loop. Panel Complexity Simple, inexpensive control panel. Limited functions. More sophisticated panel with microprocessors, digital display, and advanced programming. Conventional vs Addressable Fire Alarm Systems: Pros and Cons Aspect Conventional Systems Addressable Systems Pros – Time-proven and simple design.– Devices and panels are generally less expensive.– Straightforward panel logic; minimal programming needed.– Effective for very small facilities (single-story, few rooms).– Zone-level information is adequate in low-rise, easy-to-check buildings.– Basic troubleshooting (resistors, detector swaps) can be done by any technician. – Provides precise location of each activated device.– Continuous device status reporting improves emergency response.– Supports advanced features: section isolation, adjustable sensitivity, automatic trouble checks.– Fewer false alarms due to device-level diagnostics.– Efficient loop wiring reduces conduit and labor costs.– Easy to expand by adding devices to existing loops.– Scales well for large or multi-story facilities. Cons – Limited information: only identifies the zone, not the exact device.– Slows emergency response in large facilities (technicians must search entire zones).– More prone to false alarms: any detector issue triggers the whole zone.– Maintenance is more labor-intensive (must check multiple devices after each alarm).– Wiring is intensive: each device must be home-run to the panel.– Modifications or expansions require costly rewiring.– Limited panel zone capacity; growth may require new panels or boards. – Higher cost per device and panel due to advanced electronics.– More complex commissioning: each device needs programming and labeling.– Longer startup and configuration time.– Requires specialized training for technicians.– Repairs can be expensive; replacement components may be brand-specific.– Higher upfront investment may not be justified in small installations. Conventional vs Addressable Fire Alarm Systems: Cost Comparison Category Conventional System Addressable System Initial Installation – Cheaper hardware (basic panels & detectors)– High labor cost due to extensive wiring for each zone– Estimated $0.75–$1.25 per ft² – More expensive hardware (advanced panels & devices)– Lower labor cost thanks to lighter loop wiring– Estimated $1.00–$3.25 per ft² Maintenance Costs – Higher labor costs: technicians must manually check zones and wiring– Troubleshooting wiring faults can be time-consuming– Cheaper, widely available replacement detectors – Lower labor costs: self-testing and digital reporting simplify inspections– Fewer false alarms due to sensitivity control– Replacement parts (detectors/modules) are costlier and often brand-specific Long-Term Value – Zone-based alarms may trigger unnecessary sprinkler activation, causing costly water damage– More false alarms → downtime and fines – Precise detection can limit sprinkler activation to local area, reducing damage– Fewer false alarms → less downtime and fewer penalties– Often pays for itself over time in large/complex facilities Conventional vs Addressable Fire Alarm Systems: Installation Complexity and Scalability Factor Conventional System Addressable System Wiring Method Each zone requires a separate cable run back to the panel (home-run wiring). Devices share a common two-wire loop run out and back to the panel. Labor Intensity Labor-intensive; multiple circuits mean more conduit, cable, and terminations. Less wiring required; a single loop can cover multiple areas, saving labor and materials. Device Capacity per Circuit Typically limited (about 20–24 devices per zone per NFPA guidance). High capacity; panels can often support 99–128 devices per loop. Expansion Flexibility Limited; adding new devices often requires running new circuits and using additional zone slots. Flexible; new devices can be added by connecting them to the loop and assigning an address. Modification Effort Difficult; rewiring usually involves shutting down the system and pulling new cables through ceilings/conduits. Easier; expansion usually just requires programming new devices and possibly extending loops. Scalability Poor scalability; growth may require new panels or major rewiring. Excellent scalability; ideal for facilities that plan future expansion or retrofits. Technical Setup Simple; no device addressing required; just wiring into zones. Requires programming; each device must be assigned a unique address. Fault Tolerance A single wire break can disable an entire zone. Loops often

Best Practices for Fire Alarm System Maintenance in Commercial Buildings

Fire alarm systems are essential for early fire detection and occupant safety in any commercial building. Simply installing alarms isn’t enough; regular maintenance keeps them ready to work when needed. Facility managers and safety officers should view inspection, testing and preventive keeping as non-negotiable tasks. Routine maintenance verifies that smoke detectors, heat sensors, alarm panels and notification devices will function in an emergency. It also ensures compliance with safety regulations, minimizes false alarms and protects lives and property in workplaces. In short, proactive maintenance turns a fire alarm system from a passive installation into a reliable safety asset. In this article, we will let you know all the best practices for fire alarm system maintenance in commercial buildings. Fire Alarm System Inspection: Frequency and Key Components Regular visual inspections are the first line of defense against fire alarm failures and is one of the best practices for fire alarm system maintenance in commercial buildings. A best practice is to inspect the system at least once a year by qualified staff or contractors. In addition, facility staff should perform quick checks (for example, weekly or monthly) of obvious indicators. During inspections, use a detailed checklist covering all major components: By keeping a checklist (often provided by system manufacturers or standards), facility teams ensure no component is missed. One fire safety guide recommends scheduling annual inspections and performing frequent visual walkthroughs to catch issues early. Document every inspection result and note any anomalies in a log for follow-up. Fire Alarm System Testing: Procedures, Schedule and Safety Precautions Inspection alone is not enough; functional testing verifies the system actually works. There are two main testing approaches: Testing Schedule Testing should follow a clear schedule to balance safety and disruption. Recommended frequencies include: Whenever possible, involve the building’s maintenance team (for monitored systems) and notify the alarm company or fire department in advance. One expert guide notes: “Inform all building occupants about the upcoming test… Liaise with local fire services to avoid unnecessary emergency response”. Posting notices and alerting stakeholders reduces confusion and prevents false-alarm fines. After testing, always reset the system to normal mode and document any faults found. Safety Precautions During Testing Fire alarm tests can startle people or accidentally summon the fire department. Follow precautions to keep everyone safe and informed: By planning carefully and observing these precautions, testing can proceed without disrupting building operations or safety. Preventive Maintenance: Common Actions, Records and Professional Support Beyond scheduled inspections and tests, preventive maintenance keeps the system in top shape. This includes routine tasks that stop problems before they happen, plus good documentation and expert help. By combining in-house preventive tasks with expert service and thorough record-keeping, facility managers can keep their fire alarms reliable and ready. In practice, this means cleaning detectors, testing batteries, updating software and noting everything in a log book. These steps are relatively simple but cumulatively prevent most fire alarm failures. Regular maintenance of fire alarm systems is essential for safety in commercial buildings. It ensures that alarms truly protect people and property by functioning when needed and it keeps the building compliant with life-safety standards. By following a structured maintenance program with frequent inspections, routine testing and preventive care facilities can trust that their fire detection will not fail silently. Maintenance logs and certified technicians add further confidence and documentation of care. In short, proactive inspection, testing and upkeep make fire alarm systems reliable guardians of the workplace. As experts remind us, making fire alarm maintenance a priority provides peace of mind that the system “will function effectively in an emergency”.

How to Install Fire Alarm Control Panel?

Imagine this: it’s a regular workday in a busy office building. Suddenly, smoke begins to rise in the server room. Within seconds, the fire alarm control panel (FACP) detects the incident and alerts everyone to evacuate safely. Firefighters get the signal and respond before the fire spreads. This example shows why fire alarm control panels are not optional. They are the brains of a fire protection system. They detect threats and activate alarms. Not only this, it also coordinate emergency responses. Whether, you are a system integrator, consultant or a safety engineer. It is very important to understand the importance of fire alarm control panel. Not only this, you should also have a good knowledge of how to install and maintain an FACP in your building. In this guide, you will learn how to install a fire alarm control panel step by step. Also, We’ll cover everything from pre-installation checks to final commissioning. This guide will also be highlighting common mistakes to avoid, and share professional tips for smooth, compliant installations. Whether you are an experienced system integrator or a facility manager overseeing a project, this article will help you understand the process clearly. Step by Step Guide: How to Install Fire Alarm Control Panel (FACP) Step 1: Pre-Installation Checks Before touching a single cable or drilling a hole, you must prepare the groundwork. Proper planning prevents costly mistakes and ensures compliance with fire safety regulations. Conduct a Site Survey A well-done survey helps avoid gaps in coverage. It also prevents unnecessary rework later. Check Compliance with Standards Fire alarm systems must follow safety standards and codes. Depending on your location, you may need to comply with: Compliance is not just a legal requirement. It ensures your system is effective and reliable in real emergencies. Select the Right Fire Alarm Control Panel Not all panels are the same. Choosing the right one is critical: Pro Tip: Always consider scalability. A system that works today should also support future expansion. Step 2: Gather Tools and Materials Once you’ve finalized the design, collect the tools and materials you need. Having everything ready saves time and keeps the installation smooth. Essential Tools Materials and Accessories Pro Tip: Always use fire-rated cables. Regular electrical cables cannot withstand high heat and may fail during a fire. Step 3: Mount the Fire Alarm Control Panel The FACP should be easily accessible but also secure. Here’s how to mount it correctly: Common Mistake: Mounting the panel in hidden or locked areas without authorized access. During emergencies, this delays response. Step 4: Wire the Devices to the Panel Wiring is the most critical step. It connects every device to the brain of the system. Connecting Detectors Installing Manual Call Points (MCPs) Wiring Sirens and Sounders Pro Tip: Use different colored cables for detectors, MCPs, and NACs. This simplifies troubleshooting later. Step 5: Connect Power Supply and Backup Batteries The FACP requires a reliable power source to stay active 24/7. Common Mistake: Using undersized batteries. Always match the backup capacity to the system load to ensure compliance with required standby time. Step 6: Program the System and Configure Zones Once wiring and power connections are complete, configure the system. Define Zones Program Devices Configure Features Pro Tip: Label each zone clearly on the panel. This avoids confusion during emergencies. Step 7: Test, Commission, and Document Your system is not complete until it is tested and approved. Device Testing Power Testing Documentation Pro Tip: Always involve local fire authorities in the commissioning stage. This ensures legal compliance and builds trust. Pro Tips for a Smooth Installation of Fire Alarm Control Panel Installation Common Mistakes to Avoid Why Professional Support Matters Installing an FACP might look straightforward, but it requires expertise. A small mistake in wiring or programming can cause system failure during emergencies. That’s why professional support matters. Working with trusted distribution partners ensures you get: Conclusion: Protect Lives with Proper Fire Alarm Control Panel Installation A fire alarm control panel is more than a piece of equipment. It is a lifeline during emergencies. Installing it correctly ensures lives, assets, and businesses are protected. To recap, successful installation requires: By following these steps, avoiding common mistakes, and working with expert partners, you can build a system that is both compliant and dependable.