How Does a Fire Alarm Control Panel Work? Explained Simply

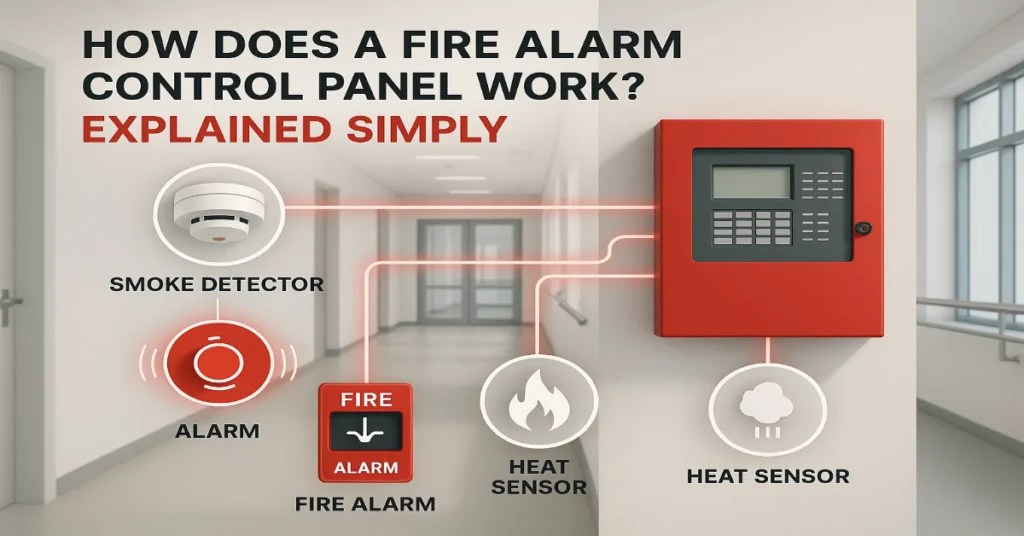

The fire alarm control panel (FACP) is often called the brain of a fire alarm system. It continuously monitors all connected initiating devices (like smoke detectors and manual pull stations) for alarm signals. When a device triggers, the panel processes the signal and decides if it indicates a fire. If so, the FACP activates all notification appliances (horns, strobes, voice evacuations) to alert occupants. It can also send control signals to shut down HVAC or release suppression systems. Importantly, the panel also supervises system health, checking for open/shorted wiring or device failures and reporting faults or trouble conditions on its display. In short, the FACP ties together detection, processing and response to alert people and systems of danger and ensuring everything is working properly. Major Components of a Fire Alarm Control Panel A modern FACP interconnects several major components and circuits. The major elements include are mentioned below: Read Also: Common Fire Alarm Installation Mistakes and How to Avoid Them FACP Signal Flow: Detection to Alert When a fire or fault occurs, the fire alarm system follows these steps: During this whole process, the panel continues to check circuits for trouble conditions (like wiring faults) and distinguishes alarm signals from supervisory signals (e.g. a valve tamper) or trouble signals, presenting any issues on its panel for maintenance. Types of Fire Alarm Control Panels Fire alarm systems come in several common types. Each type is designed for different building needs: Feature Conventional Addressable Hybrid (Mixed) Wiring Separate wires for each zone Loop wiring (one or more Signalling Line Circuits) Mixed zones and loops (vary by design) Device ID Zone-level only (no ID) Individual device address (exact location) Partially zoned; some addressable features Scale Good for small buildings Scales to large buildings and campuses Mid-size systems or retrofit projects Typical Use Homes, small offices, shops Offices, schools, hospitals, large campuses Buildings upgrading or mixing systems Cost/Flexibility Lower device cost, simpler Higher device cost, more programming needed Intermediate cost, configurable Read Also: Addressable vs Conventional Fire Alarm Systems: Which Is Right for Your Building? Residential, Commercial, and Industrial Use Fire alarm design varies by building type. Residential systems (single-family homes, small apartments) are often very simple. Many homes use self-contained interconnected smoke alarms or a small panel with a few zones. These systems cover key areas (hallways, kitchens) and are designed for ease of use and minimal maintenance. Modern “smart” home alarms may even connect to mobile apps to alert homeowners remotely, but their code requirements are lighter than for commercial systems. Commercial buildings (offices, retail stores, schools, hotels) require more robust systems. These use multiple detectors, zones or addressable loops to cover all floors and areas. They often include voice evacuation (speakers with pre-recorded messages), integration with elevators and HVAC and 24/7 professional monitoring. As one alarm provider notes, commercial panels are “engineered for size” and involve “sophisticated components” compared to residential systems. For example, a large office tower will have an addressable FACP networked across floors, a graphical annunciator showing floor plans and an automatic link to the fire department. In industrial or campus settings, panels must cover very large or risky spaces. Factories and warehouses use addressable panels with hundreds of devices, often with explosion-proof or specialized detectors in dusty or chemical environments. Multiple panels may be networked so a central control room sees alarms from all buildings. These systems may also integrate with safety interlocks. For instance, the panel can vent toxic gas or stop machinery if a fire is detected. In all cases, zoning (logical or physical) helps responders quickly narrow down where a fire occurred. Advanced Features and Integration Modern fire alarm panels offer advanced capabilities beyond simple alarm/alert. The enhanced features include: Inspection, Testing and Code Compliance Fire alarm systems are heavily regulated. In the U.S., NFPA 72 (the National Fire Alarm and Signalling Code) requires regular inspections, tests and maintenance of all fire alarm equipment. Similarly, the International Fire Code and local building codes impose strict standards. European standards (EN 54 series) define performance criteria for control panels and power supplies. These rules specify how often devices must be tested (e.g. monthly smoke detector tests, annual full system tests) and require detailed documentation of all work. Routine inspection and maintenance are essential best practices. Certified technicians should conduct scheduled tests such as activate detectors or pull stations, verify zones and outputs and check the panel’s trouble indicators. Backup batteries must be load-tested and replaced per manufacturer specifications. Accurate record-keeping is itself a code requirement like detailed logs of every inspection, test and repair must be maintained. Building managers should address any non-compliance immediately. Regular preventive maintenance, cleaning dust, tightening connections, updating software keeps the system reliable. In summary, adherence to NFPA 72 (or equivalent ISO/EN standards) and disciplined maintenance (as recommended by experts) is essential for effective fire safety. Common Issues and Troubleshooting Even well-designed fire systems can have faults. Fire safety experts should also know these common problems and fixes such as: In general, when a panel shows an alarm or trouble, technicians should read the display or annunciator for codes. Most modern panels log events and error codes that aid diagnosis. Often, a system reset, and retest is the first troubleshooting step. Clear labelling of zones and device names (as required by code) greatly speeds fault location. Keeping spare batteries and common replacement parts on hand also reduces downtime. Best Practices and Future Trends To ensure lasting reliability, follow these best practices like use qualified, licensed technicians for design and maintenance, adhere strictly to manufacturers’ specifications and keep detailed records of all service. Training building staff on alarm procedures and having clear evacuation plans enhance safety. Building-wide integration will continue growing. Panels are increasingly tied into full building management (HVAC, lighting, access control), creating unified emergency response networks. Voice evacuation and mass-notification capabilities (text alerts, public-address messaging for weather or active threats) are also being added. Longer-lasting power solutions, like solar panels or super-capacitors and wireless mesh detectors are also coming soon.

Common Fire Alarm Installation Mistakes and How to Avoid Them

Proper fire alarm installation is essential for protecting lives, property and ensuring code compliance. An incorrectly installed system can leave coverage gaps, cause false alarms or even fail during an emergency. Both contractors and facility managers must work together to follow regulations and best practices. This article explains common fire alarm installation mistakes in residential and commercial settings and provides practical steps to avoid them. Poor Detector Placement Smoke and heat detectors must be placed strategically to catch fires early without causing nuisance alarms. Putting detectors too close to kitchens, bathrooms, or HVAC vents can trigger false alarms, while placing them too far from fire-prone areas can delay detection. For example, smoke alarms installed within 10 feet of a stove often go off from cooking steam or burnt toast. Many local and NFPA codes recommend that smoke detectors be at least 10 feet (3 meters) from cooking appliances to minimize false alarms. At the same time, all sleeping areas and every floor of a house should have at least one smoke detector. Ceilings or walls near the ceiling are the best locations because smoke rises; detectors should be mounted on flat ceilings or no more than 12 inches down on walls. Avoid corners, ducts or drafty spots where air flows could bypass the sensor. Mistakes in commercial buildings are similar but on a larger scale. Detectors must cover corridors, lobbies, stairwells and high-risk areas like boiler rooms. Heat detectors or flame sensors may be better in kitchens or garages where smoke alarms cause too many false signals. Facility managers should review floor plans to ensure no blind spots in coverage. Never install detectors near fluorescent lights, unsealed vents or dead-air spaces in corners. How to Avoid Poor Placement: By carefully planning detector locations and following manufacturer and code instructions, installers ensure reliable fire detection. Facility managers should verify placement during commissioning and after any remodel, adjusting as needed to maintain coverage and minimize false alarms. Inadequate Power Supply Planning A reliable power source is essential for a fire alarm system. Every system must have a primary power connection and a secondary backup (usually batteries or a generator) to operate during outages. Underestimating power needs or ignoring backup requirements can cause the system to fail when power is lost. For example, an undersized battery may drain too quickly, disabling alarms and strobes. NFPA 72 mandates that fire alarm systems provide at least 24 hours of standby power and then 5 minutes of alarm operation. Common mistakes include using batteries with too little capacity, skipping the backup generator connection (when required), or not installing surge protection. Systems must also be wired to a dedicated circuit (often labeled “FIRE ALARM CIRCUIT”) in the breaker panel. Sharing a circuit with lights or outlets risks tripping the breaker and cutting power to the entire fire alarm panel. Neglecting to follow NFPA 72 and the local electrical code (NFPA 70) for dedicated, properly rated power feeds is a frequent violation. How to Avoid Power Supply Issues: Planned power ensures the system works even during power failures. Contractors should follow NFPA and local fire codes for standby power. Facility managers can schedule periodic battery tests and maintenance to prevent surprise power failures that compromise safety. Ignoring Local Codes and Standards Fire alarm work is heavily regulated. Ignoring local and national codes during installation is a critical mistake. Codes (such as NFPA 72) dictate everything from device spacing to notification appliance volumes to power requirements. Failure to meet these rules can result in system malfunctions, failed inspections, fines and increased liability. For example, some jurisdictions require specific features like carbon monoxide detectors in homes or voice evacuation in large occupancies. ADA standards also require strobe placement for hearing-impaired occupants. Overlooking these regulations may render a system non-compliant. Contractors must stay current with the latest editions of NFPA 72 and local fire/building codes. Many cities adopt the International Fire Code (IFC) or state-specific amendments that update NFPA requirements. Simply installing “typical” setups without verifying code can miss critical obligations, such as interconnecting smoke alarms in existing homes or providing remote annunciators in a control room. Facility managers, meanwhile, should ensure any installer is certified and aware of local requirements. They should also maintain documentation of code compliance (e.g. permits, inspection sign-offs) in case of audits. How to Avoid Code Violations: By proactively addressing codes, contractors avoid costly rework and ensure systems are accepted. Building managers should stay informed about code updates and include compliance checks in their safety plans. Improper Wiring or Device Mounting Faulty wiring and unstable device installation are common errors that undermine fire alarm reliability. Using the wrong wire gauge, connecting wires insecurely or failing to ground properly can cause intermittent faults or prevent alarms from activating. For example, tying fire alarm wires into a standard electrical junction box without a listed fire alarm block can allow short circuits or crosstalk. Likewise, mounting detectors or pull stations incorrectly (too loose, at wrong height, or without proper backboxes) leads to failures. Smoke detectors must lie flat on ceilings and pull stations should be firmly anchored at 42-48 inches above the floor. Crushing or kinking cables during installation is another issue. Fire alarm cables should be run in appropriate conduits or secured trays and kept separate from other electrical and data lines to avoid interference. Cables like FPL (plenum-rated) and FPLP (plenum for drop ceilings) are typically required for protected spaces. Skipping the use of correct cables or failing to secure them (with clamps, ties or raceways) violates code and risks damage over time. How to Avoid Wiring and Mounting Errors: By adhering to wiring standards and securely fastening every device, installers build systems that work every time. Training electricians and using experienced fire alarm technicians can prevent many of these errors. Facility managers should inspect exposed wiring and conduit to ensure nothing is pinched or dangling and verify that pull stations, horns and detectors are tightly fastened in their locations. Lack of System Integration and Testing Modern fire alarm systems often need