Zoning and Mapping in Large Building Fire Alarm Systems

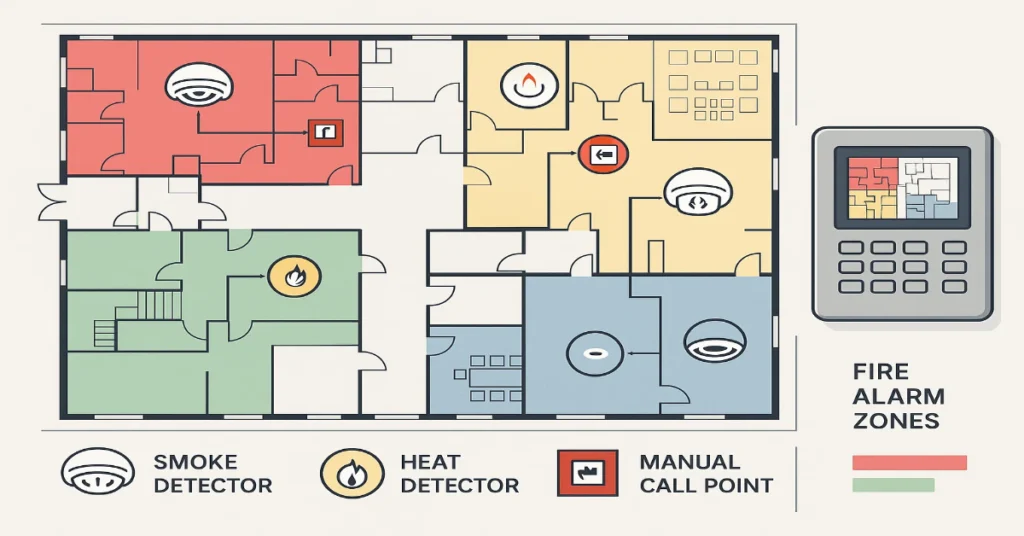

In large industrial buildings, a fire alarm system must pinpoint fires quickly and guide evacuation. Zoning divides a building into manageable sections (zones) for fire detection, while mapping ties each zone or device to a building floor plan or layout. For example, an addressable fire alarm can “divide the building into zones” that are each monitored independently. If a detector in Zone 5 triggers, the control panel indicates “Zone 5” in alarm, and a graphical map can highlight the exact location. In practice, zoning means grouping detectors and call points into labeled areas, and mapping means linking those areas to visual floor plans. This helps responders know where to go. In short, zoning breaks a complex building into clear areas, and mapping shows these areas on a schematic for rapid response. Zoning and mapping are critical in large buildings because speed and clarity save lives. In a small shop one panel might cover the whole building, but in a multistory warehouse or factory, an undifferentiated alarm would force searchers to comb the entire facility. As one safety consultant notes, zoning a big facility means “breaking a building into manageable sections for fire detection and response”. Types of Fire Alarm Zones Fire alarm zones come in several types, each serving a purpose. Key categories include detection zones, alarm (evacuation) zones and evacuation zones (or phased evacuation zones). Each type of zone should be clearly documented on the fire alarm drawings and control panel. Detection zones might be listed on the panel display, while evacuation zones could be highlighted on posted zone maps. By using zones strategically, facility managers ensure that when an alarm triggers, everyone knows exactly which part of the building is affected and how to respond. Mapping and Real-Time Response Beyond naming zones, modern systems often provide real-time mapping on screens or panels. Mapping means overlaying alarms on a floor plan or graphical building model. When a detector goes off, its symbol lights up on a digital map. This visual display helps quickly pinpoint the fire’s location in a way words or numbers alone cannot. Graphic fire-monitoring stations (for example, Simplex TrueSite or Honeywell’s IFP-Net) illustrate the value of mapping. In an emergency these systems “gather information from thousands of devices and display it on an easy-to-read, 3D graphical representation of your facility”. The operator sees not just “Zone 5”, but the exact floorplan with the alarmed detector highlighted. Built-in “autonavigation” can even zoom straight to the affected area. This immediate context is a force-multiplier: responders can visually confirm that, say, a smoke detector in the northeast corner of Floor 2 is active. In practical terms, mapping guides crews down the correct hallway and to the precise room, shaving crucial minutes off the search. Mapping also supports decision-making. For example, if an alarm appears on the east side of a plant, the safety officer may send fire brigade units to the closest external entrance on that side. If multiple alarms light up, the map shows how fire or smoke is spreading. Mapping thus turns abstract alerts into a situational diagram. According to Honeywell, the operator “receives real-time information… showing right where the event is occurring”. Some systems link mapping to instructions: on an alarm, they may display “Fire Floor 4 – Lobby” on-screen. Fire Alarm Control Panels and Annunciators The fire alarm control panel (FACP) is the system’s brain and user interface. It continuously monitors devices and reports any alarms or faults. When a detector or manual call point triggers, the panel processes the signal, activates alarm horns/strobes, and displays which zone is affected. For non-addressable (conventional) systems, the panel shows only a zone number. For addressable systems, many panels can display exact device IDs or locations. In either case, the panel (and any remote annunciators) will light up an indicator labeled with the triggered zone or device. An annunciator panel is essentially a remote display, often installed at a guard desk or entrance that mimics the main panel’s information. It may be a simplified LCD or LED board that shows active alarms, troubles and disables. For example, a wall-mounted annunciator might have LEDs for Zone 1, Zone 2, etc. In the event of alarm, it alerts staff what the main panel shows. As one source notes, an annunciator “acts as a centralized display panel” giving “real-time updates about the status of individual alarms or alarm zones”. This is crucial in buildings where the FACP might be in a locked room; annunciators allow any security or staff to see alarm status at a glance. Together, the FACP and annunciators form the control/indicating equipment. The FACP also logs events, sounds public address or voice evacuation messages (if equipped) and sends signals to external monitoring. In large networks, multiple panels can be linked. According to NBC 2016, fire alarm panels in a network should be connected in a peer-to-peer fashion or with redundant cabling, so if one link fails the others still operate. Each panel must still function as a standalone unit if disconnected. This ensures that even if a communication cable is cut by fire, each panel can still drive local alarms and display its zones. Integration with Building Management Systems (BMS) Modern buildings aim for integrated safety and efficiency, making fire alarm-BMS integration a key feature. A Building Management System (BMS) can tie together HVAC, lighting, elevators, access control and alarms. By linking the fire panel to the BMS, a fire event can automatically trigger numerous life-safety actions. For example, in a fire in an industrial building, the BMS might shut down fans to limit smoke spread, close dampers on ventilation ducts, command elevators to return to lobby (to prevent elevator use), and turn on emergency lighting in evacuation routes. If doors have electromagnetic locks, the BMS can unlock them to ensure egress. Two-way communication is common: the fire panel can signal the BMS, and the BMS can send commands or queries to the fire panel. As one systems integrator explains, this allows coordinated action: “in a fire… [the system] could close

Advanced Fire Detection Technologies: Smoke, Heat, CO, and Multi-Sensor Systems

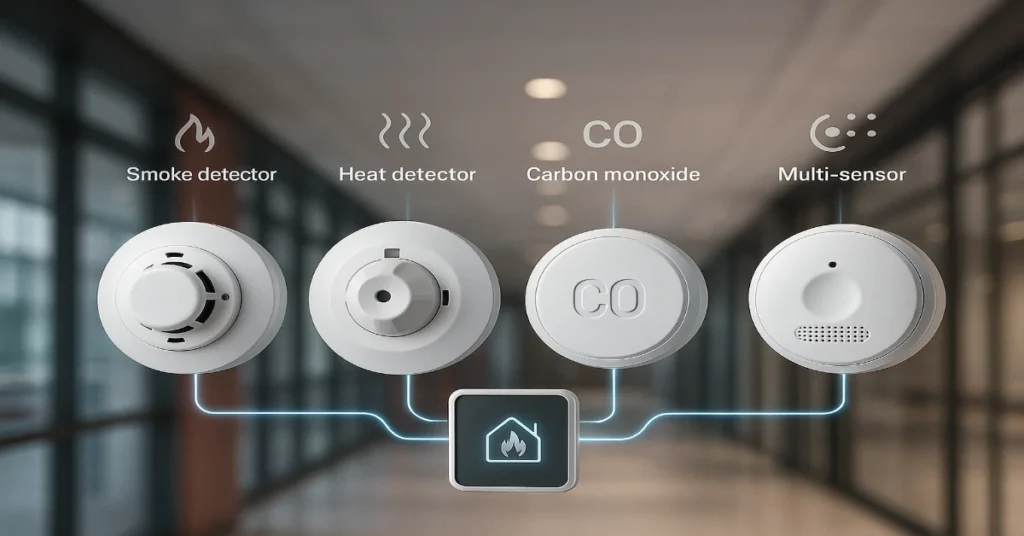

Early and reliable fire detection is essential in commercial and industrial facilities, where fires can threaten human life, expensive equipment and continuous operations. For example, the U.S. Fire Administration reports that in 2022 commercial fire losses exceeded $411 million due to equipment and detection failures. Advanced Fire Detection Technologies helps facility managers and safety officers catch fires in the incipient stage, minimizing damage and downtime. In large factories, warehouses, data centres or high-risk plants, every second of warning is valuable. Modern fire alarms protect assets and people by detecting heat, smoke, toxic gas, or combustion signatures faster and more accurately than older systems. Commercial systems differ from home alarms: they must cover vast areas, harsh environments and avoid false alarms that disrupt operations. Traditional fire alarms used simple detectors (e.g. a single smoke detector or heat sensor per room) tied to a central panel. By contrast, advanced systems incorporate multiple sensor types, network connectivity and intelligent processing. Traditional vs. Advanced Fire Detection Aspect Traditional Fire Detection Advanced Fire Detection Detection Method Single-criteria devices (e.g., smoke or heat only) Multi-sensor devices (smoke, heat, gas combined) Technology Basic photoelectric or fixed-temperature detectors AI/IoT-enabled detectors with data analysis Wiring & Connectivity Hardwired to control panel Supports wireless and IP-based connections Response Process Alarm triggered, manual response by staff/firefighters Automated alerts with remote/mobile notifications Accuracy Higher risk of false alarms (e.g., dust/steam) Can differentiate between harmless conditions and real fire Integration Standalone system with limited connectivity Integrates with Building Management Systems (BMS) Best Suited For Small/simple buildings Large, complex, modern facilities Overall Capability Basic fire detection Smart, predictive, and real-time fire safety Smoke Detection Photoelectric Smoke Detectors: Photoelectric (optical) smoke detectors contain a light source and a photodetector in a sensing chamber. In normal conditions the light beam does not hit the sensor. When smoke enters, the particles scatter the light and some of this scattered light strikes the detector, triggering the alarm. These detectors are especially sensitive to large smoke particles from smoldering fires (like smoldering wood or cables). Ionization Smoke Detectors: Ionization detectors use a tiny radioactive source (Americium-241) to ionize air molecules between two electrodes. This creates a constant electric current in clean air. When small combustion particles from a fast-flaming fire enter the chamber, they attach to the ions and interrupt the current flow. The drop in current triggers the alarm. Ionization sensors react quickly to fast flames and fine smoke (like from burning paper or liquids). Aspirating Smoke Detection Systems: In large or sensitive facilities (data centres, clean rooms, telecom vaults), aspirating detectors offer very early smoke detection. These systems use fans to continuously draw air through a network of small pipes placed throughout the protected area. The sampled air is filtered and delivered to a central detection unit that contains highly sensitive optical sensors and sophisticated processing algorithms. Because aspirating detectors actively circulate air, they can catch even trace amounts of smoke long before a standard ceiling detector would trigger. Large industrial spaces such as warehouses and factories often use aspirating smoke detection to cover wide areas. These systems actively sample air and can detect minute smoke particles for very early warning of fires. Their high sensitivity and sophisticated filtering make them effective even in dusty or high-airflow environments. Heat Detection Heat detectors respond to changes in temperature rather than smoke. This makes them useful in environments where smoke detectors could be triggered by nuisance sources. Heat detectors are also simpler and cheaper than many smoke detectors. There are two main types: Many systems use combination detectors that incorporate both fixed and rate-of-rise functions. This provides the benefits of both: the detector will alarm either on a quick heat jump or if a critical temperature is reached. Combination units improve reliability in spaces with varying conditions. In practice, industrial facilities often employ both types: fixed-temperature detectors in dusty or hot areas and rate-of-rise units in mechanical or loading zones where rapid fires can occur. Carbon Monoxide (CO) Detection Carbon monoxide (CO) detectors add another layer of fire detection, especially in areas with fuel-burning equipment. CO is a colorless, odorless gas produced by incomplete combustion (e.g., from boilers, backup generators, engines). Rising CO levels can indicate a smoldering fire that is not yet producing smoke. For commercial use, electrochemical CO sensors are the standard technology. An electrochemical CO sensor contains a small gas-permeable chamber with electrodes and an electrolyte. When CO enters the chamber, it undergoes a chemical (redox) reaction at the working electrode, generating an electrical current proportional to the CO concentration. This current is measured and used to trigger an alarm or signal. Electrochemical sensors are highly sensitive to CO, have low power needs and perform accurately over a wide range. In industrial settings, dedicated CO detectors are placed in boiler rooms, parking garages, loading bays, or near vehicles to alert staff of leaks or incomplete combustion. Today’s combined detectors often merge smoke and CO sensing in one device for convenience and comprehensive coverage. Early CO detection protects workers from poisoning and can even serve as a fire indicator: many fires release CO before thick smoke, so a rising CO reading can prompt an alarm before visibility or heat rise appreciably. Multi-Sensor Fire Detection Systems Multi-sensor or multi-criteria detectors combine several sensing elements in one unit. A typical multi-sensor device might include a photoelectric smoke chamber, a heat sensor and a CO sensor, all feeding data to an internal microprocessor. By analyzing these multiple data streams together, the detector can make more informed decisions. For example, a detector might require both smoke and heat signals before alarming, or interpret a combination of mild smoke plus rising CO as a likely smoldering fire. This cross-checking of sensor inputs reduces false alarms: benign conditions (dust, humidity, steam) will not simultaneously trigger all channels like a real fire would. Multi-sensor detectors are highly useful in sensitive environments such as manufacturing labs or chemical plants, where routine processes might emit smoke or fumes. By recognizing the unique “signature” of a