Fire Alarm Control Panel Wiring Diagram Explained

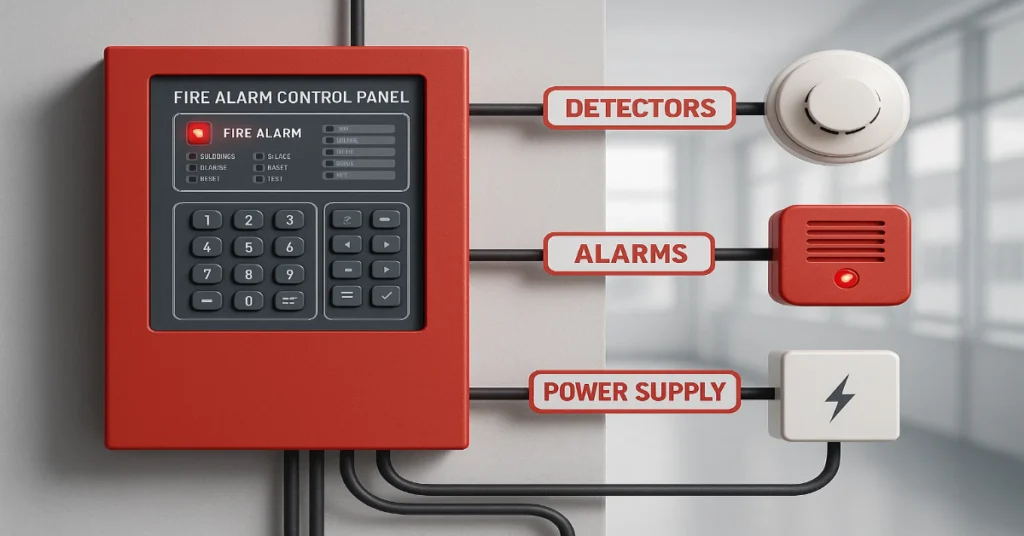

A Fire Alarm Control Panel (FACP) is the central hub of a fire alarm system. It monitors fire detection devices, activates alarms and communicates alerts to occupants and fire services. Understanding how to wire an FACP is essential for designing a reliable and efficient fire alarm system. This article explains FACP wiring, types of panels and wiring diagrams in a simple and professional manner. What is an FACP Wiring Diagram? An FACP wiring diagram is a schematic representation of how different components of a fire alarm system connect to the control panel. It shows the flow of power, signals and communication between devices such as detectors, alarms, manual call points and modules. Following the correct wiring diagram ensures the system works reliably and meets fire safety standards. Types of Fire Alarm Control Panels and Their Wiring Fire alarm systems can be broadly categorized into Conventional and Addressable systems. Each type has a unique wiring method. 1. Conventional Fire Alarm Control Panel In conventional systems, detectors, sounders and call points connect to the control panel through dedicated wiring. Devices are divided into zones (e.g., Zone 1 for basement, Zone 2 for ground floor). Zones help identify the affected area, but the system cannot pinpoint the exact triggering device. A conventional FACP divides a building into zones. Each zone can include multiple devices. When a detector activates, the panel identifies the zone but not the exact device. Wiring Diagram: Key Features: 2. Addressable Fire Alarm Control Panel Addressable systems connect devices in a loop, with each device assigned a unique address. This allows the control panel to locate the exact triggered device. Loop systems isolate faults to small sections, ensuring the rest of the system functions. One loop can handle up to 99 devices and extend up to 3.3 km, depending on the panel. Addressable systems provide higher accuracy than conventional systems but cost more. An addressable FACP assigns a unique address to each device. The panel can pinpoint the exact location of a triggered device, making it ideal for large or complex buildings. Wiring Diagram: Key Features: 3. Hybrid Fire Alarm Control Panel A hybrid FACP combines conventional and addressable technologies. It allows zones with conventional devices while using addressable devices in critical areas. Wiring Diagram: Key Features: Types of Fire Alarm Detectors Fire alarm systems use a variety of detectors, ranging from basic manual call points (break glass units) to advanced multi-sensor detectors. The main categories include: Smoke Detectors Smoke detectors operate based on different principles: Heat Detectors Heat detectors sense temperature changes. When heat rises to a preset threshold, a heat-sensitive eutectic alloy melts, similar to a fuse, triggering the alarm. Carbon Monoxide (CO) Detectors CO detectors measure carbon monoxide levels using electrochemical sensors. When CO levels exceed a set limit, the detector triggers the alarm. Fire alarm CO detectors respond faster and more sensitively than residential CO detectors, which protect against incomplete combustion in appliances. Multi-Sensor Detectors Multi-sensor detectors combine heat, optical and CO sensing capabilities. They analyze multiple inputs to detect fires accurately while minimizing false alarms. Intelligent multi-sensor detectors communicate the exact nature of the threat to the control panel. Manual Call Points Manual call points (break glass units) allow occupants to trigger alarms manually. Install them 1.4 meters above floor level, with a maximum spacing of 30 meters. They should be placed near staircases, exits and entry points to open-air areas. Essential Tips for FACP Wiring Understanding FACP wiring diagrams is essential for a safe and efficient fire alarm system. Conventional, addressable and hybrid panels each have specific wiring setups, advantages and applications. Following accurate wiring diagrams ensures reliable detection, fast response and compliance with safety standards. Whether you are installing a small office system or a large industrial setup, knowing how to wire an FACP is the foundation of fire safety.

What Is a Conventional Fire Alarm Control Panel? Working & Benefits

A conventional fire alarm control panel is a simple, zone-based control unit that has been used for decades in fire safety. It divides the protected area into zones, with each zone representing a broad part of the building (for example a floor or wing). Each zone uses one pair of wires that connect multiple detectors (smoke, heat, manual call stations, etc.) in parallel. When any device in a zone activates (for example a smoke detector senses smoke), that zone circuit goes into alarm. The panel then indicates which zone is in alarm but cannot tell which exact detector triggered. In practice, the panel displays three basic states for each zone: Normal (no alarm), Trouble (wiring fault), or Alarm. Because of this broad approach, conventional panels are typically used on smaller sites; they are “simple to install and cheap” and therefore remain popular for small schools, shops, offices, apartments and similar projects. Conventional panels may look quite basic on the outside, but they must handle all the main signaling. For example, the panel will supervise each zone circuit (usually with an end‐of‐line resistor) and watch for changes. In normal conditions the zone circuit is closed (supervised), but when a detector closes its contact (when smoke or heat triggers it) the panel detects a change in resistance and declares that zone as Alarm. The panel then automatically activates the Notification Appliance Circuits (NAC) to power horns and strobes, alerting occupants. What are the components of a conventional fire alarm control panel A conventional fire alarm system has several essential parts. Internally it contains a power supply (usually 24 V DC) and backup battery, zone input circuits, output circuits for alarms and indicators. Other major components include: Each of these components is wired to the panel according to manufacturer and code instructions. For detectors and manual alarms, an End-of-Line (EOL) resistor is placed at the far end of each zone to allow supervision. Notification appliances are often powered with synchronized strobe controllers. Together, these elements form the complete system. How a Conventional Fire Alarm System Works The operation of a conventional system is straightforward. It can be thought of in steps or states, as follows: Throughout, the panel is essentially responding to simple electrical changes on its zones. A conventional system only ever reports the zone level. It cannot by itself pinpoint which detector triggered, that must be determined by physically inspecting that zone’s devices. (One advantage of addressable systems is that each device reports its own address, but conventional panels do not have that capability. Common features and functions of Conventional Fire Alarm Control Panel Most conventional fire panels offer a standard set of indicators and controls to manage the system. Common front-panel features include: In short, a conventional panel’s interface is usually simple and labeled clearly. It provides basic functions like alarm indication, silence, reset, testing with little technical complexity. The panel often includes basic electronics (buzzer, minimal logic), but no device-address memory. This simplicity makes them reliable and easy to operate in the field. Advantages of conventional fire alarm systems Conventional fire alarm panels have several practical benefits, especially for smaller projects: In summary, conventional panels are prized for affordability, straightforward installation and adequate functionality in many standard applications. Limitations of conventional systems Despite their advantages, conventional panels have notable drawbacks: In essence, conventional panels work best when the protected area is relatively small and wiring is not too elaborate. For large-scale or highly critical applications, their limitations (mainly lack of device-level data and heavy wiring) make addressable systems more appropriate. Typical applications and best-use cases Conventional fire alarm panels are best suited for small to moderate-sized premises. Typical applications include: small schools, offices, retail shops, restaurants, apartment buildings, clinics and other facilities where the fire alarm requirements are straightforward. In these settings, dividing the building into a few broad zones is usually sufficient. For example, one zone could cover an entire floor or wing. Here are some examples of ideal uses for conventional panels: In general, if a fire safety inspector or engineer says you can reliably find the origin of an alarm by looking at which zone lit up (e.g., a single floor or wing), then a conventional panel is fine. For very large buildings, sprawling campuses, or facilities needing very precise location or integration with complex systems, an addressable system would be recommended instead. Installation and maintenance tips Proper installation and upkeep are essential for any fire alarm system. For conventional panels, keep these guidelines in mind: In all cases, follow the manufacturer’s installation manual closely. Many panels have specific requirements (like recommended resistor values or surge protection). Adhering to proper wiring practices and regularly servicing the system will ensure reliable fire protection. Compliance and safety standards Fire alarm panels and systems must meet national and international safety standards. In India, the relevant guidelines include IS 2189:2008 (Selection, Installation & Maintenance of Automatic Fire Detection and Alarm Systems) and the National Building Code of India (2016), Part 4 – Fire and Life Safety. These standards cover everything from detector placement to alarm signal requirements. For example, IS 2189 emphasizes rapid detection and clear alarm communication so occupants can evacuate safely. Many products used in India are designed to comply with IS 2189 and NBC 2016. In practice, installers often ensure panels meet both IS 2189 and comparable standards like NFPA 72 (USA) or EN 54 (Europe). On a product level, fire alarm panels are usually required to be approved or certified by relevant agencies. In the US, control panels are typically UL 864 listed (Underwriters Laboratories standard) and devices like smoke detectors follow UL 521/UL 268. In Europe, panels carry EN 54 certification. In India, look for ISI marking or approval from local fire authorities. Additionally, wiring should follow electrical safety codes (proper earthing, use of fire-rated cable, etc.). Note: Conventional fire alarm control panels remain a straightforward, economical choice for many installations. They effectively provide early fire warning over broad zones with minimal technology. For electrical