Why Fire Safety Engineers Prefer Addressable Fire Alarm Panels Over Conventional Systems

Fire protection has evolved rapidly over the past two decades. Modern infrastructure, strict safety norms and the need for real-time responsiveness have pushed engineers to choose better, smarter technologies. When it comes to fire alarm systems, the debate between addressable fire alarm panels and conventional systems is now largely settled. Today, most fire safety engineers strongly prefer addressable systems and for good reason. This article explains why addressable fire alarm panels have overtaken conventional systems in engineering design, implementation and long-term safety planning. You’ll learn about performance, accuracy, cost-effectiveness, compliance, integration benefits and practical use cases. 1. Understanding the Two Technologies What Is a Conventional Fire Alarm System? A conventional fire alarm panel divides a building into multiple “zones.” Every detector or manual call point (MCP) in a zone is wired in parallel. If a device is triggered, the panel can only identify which zone raised the alarm, not the exact device. Key Features: What Is an Addressable Fire Alarm Panel? An addressable system assigns a unique digital address to each device (detector, MCP, module, sounder). The panel communicates with every connected component individually and can detect exact device location and status in real time. Key Features: 2. Pinpoint Accuracy in Fire Detection One of the biggest advantages of addressable systems is precise detection. Conventional System Limitation: If a fire breaks in Zone 4, the panel alerts the user to “Zone 4 Fire.” The safety team still needs to search the entire zone to identify the exact trigger point. This wastes valuable time and causes confusion during emergencies. Addressable System Advantage: If Detector 23 on Level 5 in Room B is triggered, the system shows: “Smoke Detector – Device 23 – Level 5 – Room B” This accuracy: Why Engineers Prefer It:Pinpoint alerting supports emergency planning, floor coordination and compliance with modern safety codes. 3. Faster and More Reliable Response Time Every second counts in a fire emergency. Addressable panels use intelligent polling, which means the system continuously checks the health and status of each device. Addressable System Benefits: Conventional Panels Lag Behind: They rely on passive circuits and detect changes only when a device sends a trigger signal. This can cause delay and increase risk in large buildings. 4. Reduced False Alarms and Unwanted Disruptions False alarms are one of the most expensive and frustrating problems in traditional fire alarm setups. Why Conventional Systems Trigger False Alarms: Addressable Systems Solve This: Result: Fewer disruptions, cost savings and improved system reliability. 5. Better Scalability and Flexibility Modern facilities like airports, hospitals, factories and tech parks have complex layouts. Addressable panels are designed to scale with these environments. Conventional system limits: Addressable system flexibility: Engineers choose addressable systems for: 6. Cost Efficiency Over the System Lifecycle A common misconception is that conventional systems are cheaper. While the initial cost of conventional systems is lower, engineers evaluate the lifetime cost, not just procurement. Addressable System Cost Advantages: Over a span of 5-10 years, addressable systems prove to be more economical than conventional designs. 7. Enhanced Monitoring and Maintenance Engineers prioritize systems that simplify maintenance and reduce downtime. Addressable systems offer: Conventional systems lack: This makes addressable systems ideal for facilities with limited maintenance staff or outsourced service contracts. 8. Seamless Integration With Modern Building Safety Systems Fire alarm systems rarely operate in isolation today. Engineers choose addressable systems because they easily integrate with: Conventional systems often require separate interfaces or wired relays to connect with these services, increasing complexity. 9. Compliance With International Standards and Regulations Authorities and safety codes worldwide are moving away from conventional models. Addressable systems support: In contrast, conventional systems may fall short during inspections and may involve retrofitting costs to meet updated codes. 10. Ideal for Complex or High-Risk Buildings Engineers working on high-occupancy or mission-critical projects favor addressable panels due to complexity, regulations and risk level. Most used in: In these environments, quick detection, accurate location, system integration and reliability are non-negotiable. 11. Future-Proof Technology Technology trends in fire safety are moving toward IoT, automation, and remote control. Addressable fire panels support these advancements. Features driving the shift: Conventional systems cannot adapt to these modern enhancements. 12. Better Event Logging and Reporting Managing fire incidents requires accountability and traceability. Addressable systems provide: Conventional systems typically show only alarm and fault signals, without detailed data tracking. 13. Improved Evacuation and Safety Management Addressable panels support advanced evacuation features like: These options reduce panic, improve coordination and protect life during emergencies. 14. Why Engineers Have Shifted Their Preference Fire safety engineers no longer choose systems based on cost alone. They evaluate risk, compliance, long-term value, system intelligence and building type. Key reasons addressable systems win: The only scenarios where conventional systems still work are: For all medium to large projects, addressable is the default and preferred choice. The shift from conventional to addressable fire alarm systems is not a trend, it is a logical evolution of safety engineering. Precision, intelligence, scalability, compliance and cost-effectiveness make addressable panels the superior option in nearly every modern environment. Fire safety engineers prefer addressable fire alarm panels because they enhance life safety, emergency response and long-term efficiency. As buildings grow smarter and regulations tighten, addressable technology will dominate new installations and system upgrades across industries. If you’re involved in planning, designing, or upgrading a fire alarm system, choosing an addressable solution isn’t just a technical upgrade, it’s a strategic safety decision. Read Also: What to Check Before Buying a GST Addressable Control Panel (Engineer’s Checklist) Read Also: Wiring Architecture & Loop Design Best Practices for GST Addressable Fire Alarm Systems

Wiring Architecture & Loop Design Best Practices for GST Addressable Fire Alarm Systems

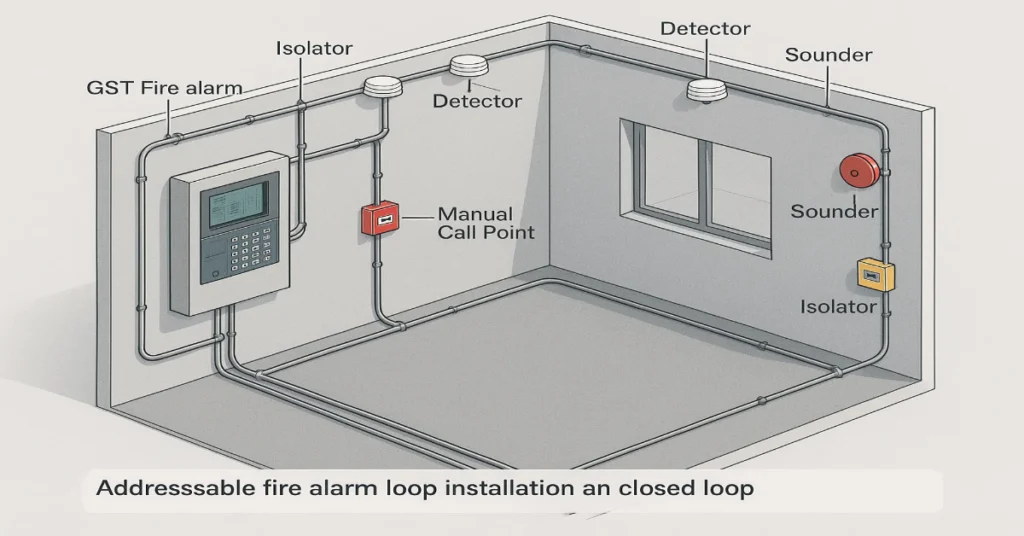

Designing a reliable GST addressable fire alarm system goes beyond selecting the right panel or detector. The real backbone is the wiring architecture and loop design. A well-planned loop layout ensures faster detection, minimizes signal loss, simplifies troubleshooting and lowers long-term maintenance costs. For engineers, system integrators, fire safety consultants and facility managers, understanding best practices in wiring is essential to ensure system performance, compliance and scalability. This guide covers everything from loop zoning to cable selection, fault tolerance, grounding and routing strategies, all aligned with real-world conditions and international installation standards. Why Wiring Architecture Matters in Addressable Fire Systems In a GST addressable system, communication happens digitally between field devices and control panels over a shared loop. Unlike conventional wiring where zones are hardwired individually, addressable systems rely on data integrity and power continuity over long distances. Poor design can lead to: By applying structured wiring principles, engineers can avoid costly redesigns, unsafe wiring paths or device outages. Understanding the Core Loop Structure A loop circuit in GST systems typically connects multiple devices like: Each loop supports a defined number of devices, usually up to 242 depending on panel capacity and device type. 🔹 Closed Loop (Preferred Design) A closed loop has two paths – outgoing and return, forming a ring. If one segment is cut or shorted, devices remain active through the opposite direction. Benefits: 🔹 Open Loop (Radial / Spur) Used when building layout or retrofit limitations apply. Devices are daisy-chained in one direction, without a return path. Drawback: A wiring break isolates all next-in-line devices.Recommendation: Keep open loops short and limited to low-risk zones. Loop Segmentation & Zoning Best Practices Divide loops strategically to balance coverage, fire sections and maintenance simplicity. Best Practices: Cable Selection Guidelines Choosing the right cable type is crucial to maintain system reliability and compliance. Recommended Cable Specs: Cable Ratings: Parameter Recommended Value Conductor Material Pure Copper Insulation FRLS / LSZH Max Length/Loop 2–3 km (with limits) Shield Aluminum foil + drain wire Managing Voltage Drop GST systems rely on stable power to communicate with all devices. Voltage drops increase with long runs and high device loads. Tips to Control Voltage Drop: Best Practices for Cable Routing Proper routing prevents electromagnetic interference, physical damage and maintenance issues. Do This: Avoid This: Using Isolators Correctly Short-circuit isolators are essential in maintaining communication during faults. In GST systems, they can be: Placement Rules: Goal: A single fault should not disable more than 30 devices. Earthing and Shield Management Cable shields reduce interference but must be handled properly. Grounding Rules: Proper earthing helps maintain signal integrity, especially in industrial or EMI-heavy sites. Fault Tolerance & Redundancy Design To maintain uptime, especially in critical buildings, build automatic redundancy into the wiring architecture. Strategies: Installation Practices to Avoid Common Failures Many site issues arise not from design but from poor installation. Here’s how to reduce them. Wiring Do’s: Wiring Don’ts: Testing & Commissioning Best Practices After loop wiring is complete, every segment must be tested before panel integration. Mandatory Checks: Maintenance & Documentation Well-maintained wiring saves time during audits and emergency breakdowns. Include: Maintain updated drawings after any modifications. GST Loop Design Example (Typical Layout) Loop 1 – Basement & Ground Floor Loop 2 – Floors 1–3 Loop 3 – Critical Areas This structure ensures isolation of faults and simplifies evacuation logic. Compliance & Standards to Follow Depending on location and project scale, align with relevant standards: Adhering during design helps pass authority inspections and lowers redesign risk. Future-Proofing Your Wiring Design As buildings evolve, fire systems must adapt without replacing entire loops. Design with: Key Takeaways Here’s a condensed list of best practices you should follow: ✔ Use closed loop architecture where possible✔ Limit devices to 150-200 per loop✔ Choose FRLS/LSZH copper cables with adequate gauge✔ Place isolators every 20 devices or per floor✔ Maintain separation from power and data cables✔ Ground shield at only one end✔ Test continuity, insulation and resistance✔ Map loops logically by fire zones✔ Document and label every cable✔ Plan for expandability and maintenance Wiring architecture is one of the most critical aspects of implementing GST addressable fire alarm systems. A robust loop layout not only ensures compliance but also minimizes false alarms, reduces downtime and simplifies long-term maintenance. For engineers, system integrators, fire safety consultants and facility managers, good wiring practices are an investment in reliability and life safety. READ AlSO: Upgrading from Conventional to GST Addressable Fire Alarm Systems: Cost & Process Guide READ AlSO: What to Check Before Buying a GST Addressable Control Panel (Engineer’s Checklist)