How to Reduce Detector Response Time Using Smart Loop Mapping

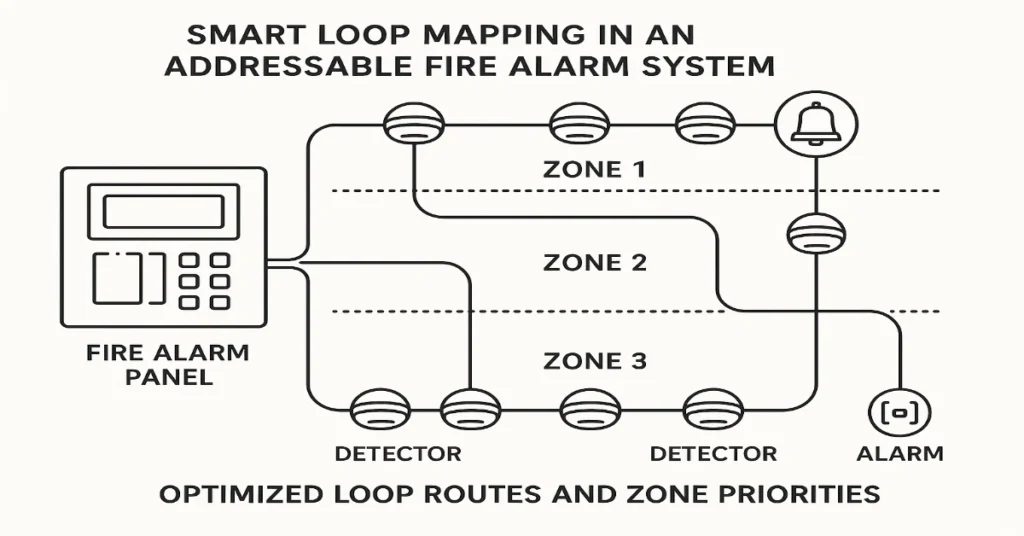

In industrial and commercial buildings, every second counts when it comes to fire detection. The faster a fire alarm system can detect smoke or heat, the quicker emergency actions can start, saving assets, production time and most importantly, lives. One of the most effective techniques to achieve this speed is Smart Loop Mapping. This method has transformed how fire alarm engineers design and configure addressable systems, drastically reducing the detector response time and optimizing system performance. In this article, we’ll explain what detector response time really means, why it matters and how Smart Loop Mapping can help engineers achieve faster, more reliable fire detection across complex facilities. What Is Detector Response Time? Detector response time is the total time it takes for a detector (like a smoke or heat sensor) to identify a fire condition and communicate that signal to the fire alarm control panel (FACP). In an ideal setup, this time should be less than 5 seconds in high-risk zones. But in large facilities, such as power plants, factories and refineries, the time can increase due to network length, communication delays and poor loop mapping. Several factors affect detector response time: Smart Loop Mapping helps overcome most of these challenges by intelligently organizing how detectors and devices communicate within a loop. Understanding Smart Loop Mapping Smart Loop Mapping is an advanced engineering method used to design and configure addressable fire alarm loops for optimal performance. It focuses on reducing unnecessary communication delays between the control panel and field devices. In a typical addressable fire alarm system, each device (detector, module, call point, etc.) has a unique address. The control panel continuously polls these devices one by one in a loop sequence to check their status. In a poorly designed loop: Smart Loop Mapping, on the other hand, uses intelligent zoning and logical addressing to minimize communication travel time and enhance real-time responsiveness. How Smart Loop Mapping Reduces Response Time Let’s break down the ways Smart Loop Mapping helps engineers optimize detector response speed: 1. Logical Sequencing of Devices Instead of connecting devices randomly, engineers assign addresses in a logical sequence, based on physical location and criticality. This ensures that the control panel receives data from critical zones sooner, cutting down overall response time. 2. Optimized Loop Length The total loop length plays a major role in how fast data travels. Long loops increase latency. Smart Loop Mapping helps engineers: By keeping each loop within optimal length (as per manufacturer guidelines), signal travel time is minimized. 3. Reduced Device Density per Loop Another smart tactic is to limit the number of devices per loop. If a single loop carries too many detectors, the panel takes longer to complete one polling cycle. Smart Loop Mapping distributes devices evenly across multiple loops so no single loop becomes overloaded. For example: This halves the communication cycle time, resulting in quicker detection and alarm processing. 4. Intelligent Prioritization Not all zones require the same priority. A high-voltage room or chemical store is more sensitive than a corridor. Smart Loop Mapping allows engineers to prioritize device polling. The control panel can check devices in critical zones more frequently than others, ensuring early warnings in high-risk areas. 5. Real-Time Fault Isolation Traditional loop configurations can slow down response times when a fault occurs. A short circuit or communication error on one device can delay the entire loop. Smart Loop Mapping integrates fault isolation modules strategically between sections. When a fault happens, it isolates the affected part automatically, allowing other sections to continue operating normally. This maintains system speed and reliability even during partial loop faults. 6. Shorter Polling Cycles Every detector in an addressable system waits for the panel to poll it. The longer the loop, the longer it takes for all devices to complete one cycle. With Smart Loop Mapping, engineers design loops in a way that ensures shorter polling cycles, meaning each device is checked more frequently, drastically improving response efficiency. 7. Intelligent Software Configuration Modern fire alarm systems, especially from advanced manufacturers like GST (Gulf Security Technology), allow engineers to configure Smart Loop Mapping through specialized software. This software uses algorithms to: This data-driven design ensures real-world performance matches expectations. Benefits of Using Smart Loop Mapping Implementing Smart Loop Mapping isn’t just about speed. It brings a full suite of benefits that improve fire safety, maintenance and scalability. 1. Faster Fire Detection By optimizing loop communication, detectors report fire conditions almost instantly, providing early warning and enabling faster evacuation or suppression actions. 2. Improved System Stability Smart mapping reduces the chances of data collisions, signal loss and polling delays. It results in a more stable and consistent fire detection system. 3. Simplified Maintenance Logical mapping means maintenance teams can easily trace faulty devices or wiring segments. It reduces downtime and simplifies troubleshooting. 4. Reduced False Alarms With optimized loop communication and intelligent zoning, detectors perform better with fewer false triggers, improving reliability and user confidence. 5. Better Integration with Building Management Systems (BMS) Smartly mapped loops integrate smoothly with BMS or SCADA platforms, providing real-time fire status data without communication lags. 6. Scalability and Future Expansion Engineers can easily add new devices or expand zones in a smartly mapped network without disturbing existing configurations. Practical Steps to Implement Smart Loop Mapping Here’s a step-by-step approach engineers can follow to create an effective Smart Loop Map: Smart Loop Mapping in Real-World Applications Let’s consider a practical example: A 200 MW power plant uses over 800 detectors across multiple floors and rooms. Initially, they experienced delays of 10–12 seconds between smoke detection and panel response. After re-engineering the layout using Smart Loop Mapping: Result: This shows how effective loop optimization can transform real-world fire safety operations. Common Mistakes to Avoid Even the best design tools can’t fix poor planning. Here are common errors engineers should avoid: Avoiding these mistakes ensures your smart loop mapping delivers its full potential. Why Smart Loop Mapping Is the Future of Fire Alarm Engineering With industries moving toward IoT-based

Why GST Fire Alarm Panels Are Engineers’ First Choice for Industrial Use

In industrial environments, safety isn’t an option, it’s a requirement. Whether it’s a power plant, refinery, manufacturing unit or logistics hub, the risk of fire can have devastating consequences. Fire Safety Engineers responsible for these critical infrastructures need fire alarm systems that are not only dependable but also scalable, intelligent and compliant with international standards. That’s where GST Fire Alarm Panels come into the picture. Known for their cutting-edge design, flexibility and robust performance, GST panels have become the first choice for engineers across industries in 2025. From smart addressable systems to advanced integration capabilities, GST ensures that engineers can design fire detection systems that work seamlessly even in the most demanding industrial conditions. 1. Built for Industrial-Grade Reliability Industrial facilities operate under harsh conditions, heat, dust, humidity and continuous vibration. Regular fire systems often struggle to maintain accuracy in such environments. GST Fire Alarm Panels are engineered for industrial reliability, offering stable operation even in challenging surroundings. The panels are built using high-grade electronic components with surge and noise protection, ensuring uninterrupted performance. Engineers prefer GST because: This level of reliability allows engineers to confidently deploy GST panels in heavy industries such as oil & gas, power generation, manufacturing and data centres. 2. Addressable Technology: Precision and Control Traditional fire alarm systems can be slow to locate the exact source of a fire, leading to costly delays in response. GST’s addressable fire alarm panels solve this issue through smart detection and identification. Each device in the GST addressable loop, whether a smoke detector, heat sensor or manual call point, has a unique address. When an alarm is triggered, the system instantly identifies the exact location of the incident. For engineers, this offers three major advantages: The result is enhanced situational awareness and a more reliable protection network across the facility. 3. Scalable Design for Large Industrial Sites Industrial complexes are vast and often spread across multiple zones or buildings. Scalability is a critical factor for engineers during system design. GST’s range of fire alarm panels, such as the GST200N, IFP8 and GST5000, are designed with scalability in mind. They can handle multiple loops, allowing connection of thousands of devices without compromising speed or reliability. Engineers can easily expand the system as the facility grows, thanks to: This flexibility makes GST a preferred choice for industrial zones, smart factories and multi-building projects. 4. Seamless Integration with Other Safety Systems Modern industrial safety relies on system integration. Fire detection, suppression, access control, CCTV and BMS (Building Management Systems) must work together to ensure comprehensive protection. GST Fire Alarm Panels are designed for seamless integration with third-party systems through open protocols and interfaces. Engineers can link GST panels with: With RS485, Modbus and TCP/IP communication options, GST enables centralized safety monitoring and automation. Engineers benefit from simplified system management and coordinated emergency response across the entire facility. 5. Intelligent Monitoring and Remote Control In the age of Industry 4.0, remote supervision is essential. GST’s latest fire alarm panels come with smart monitoring capabilities that enable real-time supervision, fault analysis and event logging. Engineers can access system status remotely via GSTDefender or networked fire monitoring software, offering: This level of intelligence reduces the need for manual inspections and allows proactive maintenance, something engineers value highly in large-scale operations. 6. Cost Efficiency Without Compromise Industrial fire systems are major investments and cost efficiency is always a deciding factor. GST Fire Alarm Panels deliver value for money by combining performance, scalability and longevity. Key cost-saving advantages include: Engineers appreciate that GST offers high-end reliability at competitive pricing, making it one of the most cost-effective solutions in the market. 7. User-Friendly Interface and Configuration Complexity can be a barrier in large-scale installations. GST panels feature an intuitive user interface that allows engineers and technicians to configure, monitor and test systems without specialized programming skills. Features that enhance usability include: This not only reduces commissioning time but also minimizes the need for extensive training, important when multiple teams are involved in project execution. 8. Global Certifications and Compliance Industrial engineers often work on projects that require international safety compliance. GST panels are globally recognized and certified, giving them a strong reputation for quality and reliability. They meet stringent standards like: These certifications make GST panels suitable for multinational industrial projects, ensuring they comply with both local and international regulations. 9. Trusted by Engineers Worldwide GST, a brand under Gulf Security Technology, has over two decades of experience in fire safety innovation. Its panels and devices are deployed across more than 100 countries, protecting industries ranging from oil & gas and manufacturing to airports and hospitals. Engineers trust GST because of: This global trust reinforces why GST is not just a system, it’s a long-term safety partner for industrial engineers. 10. Real-World Industrial Success Stories To understand GST’s real impact, consider a few examples: These practical results demonstrate how GST delivers safety, continuity and reliability, three pillars every engineer looks for in industrial applications. 11. Comprehensive Product Range for Every Project GST doesn’t follow a one-size-fits-all approach. Engineers can choose from a wide range of panels based on project requirements: Model Type Ideal Use Case GST100 Series Conventional Small industrial zones and warehouses GST200N Series Addressable Mid-size factories, logistics and manufacturing units IFP4E / IFP8 Series Intelligent Addressable Large plants, refineries and multi-building projects GST5000 Networkable Intelligent Large-scale industrial or mixed-use developments This flexibility ensures that every industrial project from a single plant room to a massive production campus, can find a perfectly matched GST solution. 12. The Engineer’s Advantage: Simplified Design and Reliable Operation Ultimately, GST fire alarm panels give engineers an edge. With user-friendly software, open communication protocols and reliable field devices, they simplify every stage of the project, design, installation and maintenance. Engineers can easily: In high-stakes industrial projects, these advantages translate to reduced commissioning time, fewer site issues and better long-term reliability. GST – The Industrial Standard in Fire Safety When it comes to industrial fire protection, engineers prioritize performance, flexibility and reliability,