Addressable vs. Conventional Fire Alarm Panels From an Engineering Perspective

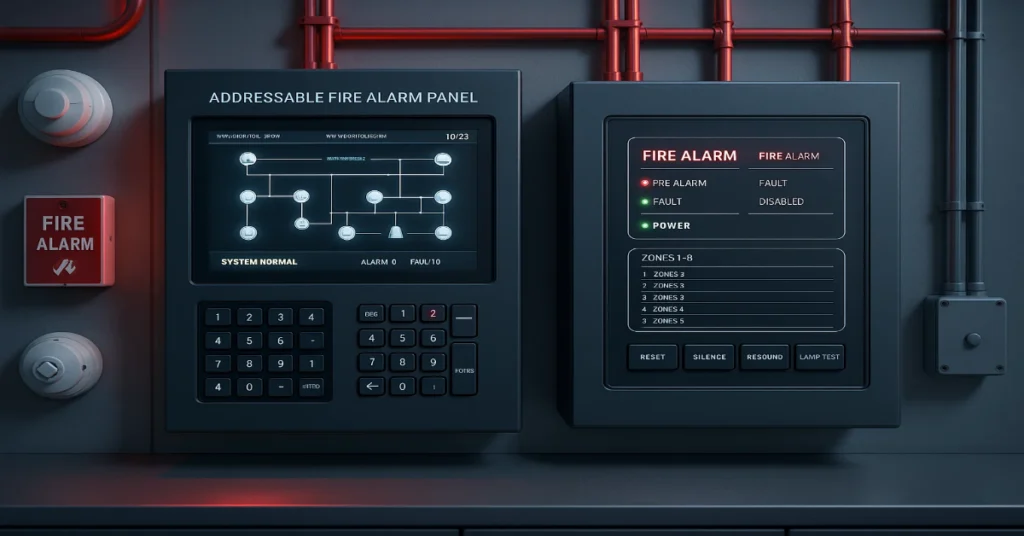

Fire protection engineering has evolved rapidly over the past decade. Today, industries, commercial complexes and high-rise buildings expect fire alarm systems that are not only reliable but also intelligent, scalable and compliant with the latest codes. This demand has intensified the debate between addressable and conventional fire alarm panels. From an engineering perspective, these two systems follow the same core purpose, detecting fire early and notifying occupants. However, their architecture, communication method, design workflow, maintenance cost and long-term scalability differ significantly. This article provides a deep engineering comparison, explaining how each system works, where it fits best and why many engineers prefer modern addressable systems, especially in growing markets like India. Understanding the Core Architecture To evaluate both systems, engineers first look at how the devices communicate with the panel. Conventional Panels: Zone-Based Architecture A gst conventional fire alarm system divides the building into zones. Each zone connects several detectors and call points via parallel wiring. When an alarm triggers, the panel displays the specific zone but not the exact device. Characteristics: Addressable Panels: Device-Specific Intelligent Architecture An gst addressable fire alarm panel assigns unique digital addresses to each device. This enables two-way communication between the panel and every detector or module. The panel can identify the exact device, its condition and even pre-alarm data. Characteristics: Engineering Comparison: How Each System Performs Engineers evaluate fire alarm panels on real-world parameters that directly impact safety, cost, maintenance and code compliance. Below is a clear comparison. Wiring Design and Installation Conventional System Wiring The wiring topology is relatively simple but rigid: Engineer’s Note:This increases both material cost and labour cost, especially for multi-floor buildings. Addressable System Wiring Addressable panels use loop wiring, which allows many devices on a single circuit. Engineering Advantage:Up to 30–40% cable reduction is common in large projects, lowering overall cost of installation. Accuracy of Fire Detection Conventional Detection Accuracy Because several detectors share the same zone, the system can only indicate that a “Zone 3 Alarm” occurred. Engineers then need to manually inspect: This delays response during critical seconds. Addressable Detection Accuracy Addressable systems pinpoint the exact device and its address: Modern addressable panels even support environmental drift compensation, reducing false alarms. Why Engineers Prefer This:Clear localization drastically improves evacuation decisions and fire-fighting strategy. System Reliability and Fault Management Conventional Panels Fault notifications are limited: Addressable Panels Addressable panels provide deep system diagnostics: If a cable cuts, isolators localize the problem and the rest of the loop remains operational. Engineering Impact:Improves uptime and reduces maintenance cycles significantly. Scalability and Future-Proofing Conventional Panels Scaling is difficult: Suitable only for small projects such as: Addressable Panels Addressable panels are built for future flexibility: Modern brands like GST offer addressable systems with modular loop expansion and communication cards, making upgrades smooth and cost-efficient. Maintenance and Life-Cycle Cost Conventional System Maintenance Maintenance is manual and time-consuming: This increases long-term cost. Addressable System Maintenance Addressable systems are engineered for efficient maintenance: Over a 10-year cycle, an addressable system often delivers 30-50% lower operational cost due to reduced downtime and maintenance hours. Fire Response Strategy and Evacuation Management Conventional Panels Conventional systems do not provide advanced evacuation logic: Addressable Panels Modern addressable panels support sophisticated evacuation management: This is essential for high-density buildings like IT parks, malls, hotels and airports. Integration with Modern Safety Ecosystem Conventional Panels Integration possibilities are limited: Addressable Panels Engineers appreciate the seamless integrations: This creates a smarter safety ecosystem. Cost Comparison: Initial vs Life Cycle Initial Cost Conventional panels have: Addressable panels have: Life Cycle Cost When engineers evaluate cost across 10–15 years, addressable systems are more economical due to: Compliance with Indian and International Standards Conventional Panels Conventional systems are compliant with: But they may not meet advanced safety requirements for: Addressable Panels Addressable systems align with: With 2025 updates focusing heavily on smart systems, addressable panels are future-ready for compliance. From an Engineer’s Perspective: Which One Should You Choose? Choose Conventional If: Choose Addressable If: In 2025, more than 70% of medium and large commercial projects in India (as per industry observations) have shifted to addressable panels due to greater reliability and future readiness. Why Many Engineers Prefer GST Addressable Panels GST is widely adopted across India because: This makes GST a trusted choice for consultants and integrators. What Matters Most in 2025? From an engineering perspective, the choice between addressable and conventional fire alarm panels depends on: Conventional systems still serve small spaces well, but addressable panels have become the engineering standard for modern infrastructure. They offer precision, scalability, lower life-cycle cost and powerful integration capabilities, making them the smarter long-term choice. A well-designed addressable system ensures faster detection, quicker evacuation and higher compliance, ultimately contributing to a safer, smarter, more future-ready building. Read Also: Why Fire Alarm Systems Are the First Layer of Industrial Safety Read Also: Where to Buy Original GST Addressable Fire Alarm Panels in India

Why Fire Alarm Systems Are the First Layer of Industrial Safety

Industrial facilities operate in environments where risks are unavoidable. Whether it is heat-intensive machinery, chemical storage, high-voltage equipment or continuous manufacturing lines, every site carries a combination of mechanical, electrical and operational hazards. Because these risks cannot be eliminated fully, industries depend on multiple layers of safety to protect their people and assets. Among all these layers, the fire alarm system stands out as the very first line of defence. It is the earliest indicator that something is wrong. It alerts people, triggers automated safety mechanisms and reduces the chances of escalation. To understand why fire alarm systems play this crucial role, we must look at how industrial safety is structured, especially through the globally accepted framework known as the Hierarchy of Controls. Understanding the Hierarchy of Controls in Industrial Safety The Hierarchy of Controls is a safety model used worldwide by engineers, fire auditors and safety professionals. It ranks hazard-control methods by effectiveness, typically represented as a pyramid with five levels: In most industrial environments, hazards cannot be entirely eliminated or substituted. Machines must operate. Chemicals must be stored. High-voltage power must run across the facility. This means the most practical and effective approach comes from engineering controls, where automated systems minimize risks without relying on human reaction. Fire alarm systems fall exactly under this category. Where Fire Alarm Systems Fit in the Hierarchy of Controls Fire alarm systems are classified as Engineering Controls because they automatically detect early signs of fire and warn people without requiring human involvement. While other engineering controls such as fire doors, smoke dampers, ventilation control and suppression systems act as barriers, none of them function effectively without a detection system to activate them. In this way, fire alarms create the bridge between hazard and response. Without early detection, suppression systems may activate too late or not at all, administrative controls may never be triggered and PPE may not be used in time. This is why fire alarm systems, though technically placed under engineering controls, act as the first active layer of safety in any industrial facility. Why Fire Alarm Systems Form the First Layer of Industrial Safety Fires in industrial environments can escalate rapidly. A spark in a panel, overheating in a motor, a small leak of a flammable substance or the ignition of dust particles can turn into a large-scale incident within minutes. Fire alarm systems detect these early shifts, before they become dangerous. They serve as the first line of defence for several reasons: Early Detection Saves Lives and TimeA fire often begins small: a temperature rise, a spark, or smoke formation. Fire alarms detect these subtle indications immediately, giving people crucial time to evacuate and operators time to activate safety procedures. Human Observation Is Not EnoughIndustrial zones are large and noisy and some areas are unmanned or hard to access. Relying on workers to notice fire signals is slow and unreliable. Automated detection eliminates delays and ensures around-the-clock monitoring. All Other Safety Systems Depend on the Alarm SignalSuppression systems such as sprinklers, CO₂ flooding, water mist or foam systems rely on detection to activate correctly. HVAC shutdown, smoke extraction, fire door closing and lift recall also depend on signals from the fire alarm panel. Damage Control Begins With Swift ResponseThe earlier a fire is detected, the lower the risk of property loss, downtime, production stoppage and financial impact. Insurance agencies, compliance bodies and auditors all emphasize early detection for this reason. Workers Need Guidance During EmergenciesModern fire alarm systems provide voice evacuation messages that guide workers toward safe exits. In industries where people may panic or become disoriented, this function is a lifesaver. Because of these factors, the fire alarm system becomes the first layer, activating protective actions before anyone even sees visible danger. How Fire Alarm Systems Strengthen Each Layer of the Hierarchy of Controls Even though fire alarms sit under engineering controls, they support every level of the safety hierarchy. Supporting Elimination and SubstitutionBy tracking events and incidents, fire alarm logs help engineers identify unsafe processes and improve them. If a particular machine consistently triggers alarms, it indicates deeper issues that may require substitution or removal. Supporting Engineering ControlsFire alarms integrate with systems like fire doors, suppression units, smoke dampers, AHU shut-downs and intelligent BMS platforms. The entire chain of engineering safety depends on the fire alarm system’s prompt detection. Supporting Administrative ControlsAlarm events help improve SOPs, refine training and document emergency responses. Evacuation drills initiated by alarms ensure readiness. Supporting PPE UsageWhen alarms activate, workers know instantly to use breathing masks, fire hoods or protective gear, especially in chemical or gas-based environments. In this way, fire alarms indirectly improve every layer of industrial safety. Components That Make Fire Alarm Systems Essential in Industrial Sites A high-quality industrial fire alarm system contains several core components that work together to detect and respond. Fire Alarm Control Panel (FACP)This is the central control unit that receives detector signals, processes them and triggers warnings. DetectorsDifferent detectors handle different environments: Industries often use a hybrid setup for precise detection across various zones. Manual Call PointsWorkers can raise an alarm if they spot smoke or fire before detectors do. Notification DevicesHorns, strobes, sirens and voice evacuation systems instantly alert people even in noisy factories. System IntegrationsModern fire alarm systems integrate with: GST Fire Alarm Systems in Industrial Safety While many fire alarm brands exist in the market, GST (Gulf Security Technology) has gained strong trust in industrial environments because of its stability, reliability and integration capabilities. GST systems are widely used in: Some of the key reasons engineers prefer GST include: This soft mention helps readers understand that GST is one of the reliable options when planning industrial safety systems, without making the article promotional. Why Engineers and Facility Managers Prioritize Fire Alarm Systems Industrial safety is ultimately a responsibility shared across departments, electrical, mechanical, EHS, operations and management. Among all tools available, fire alarm systems remain essential because they deliver the fastest possible response. In high-risk environments, quick action determines whether