Which Type of Detector Should You Buy for Hospitals, Hotels & Industrial Sites?

Fire detection requirements vary widely across different types of buildings. A detector suitable for a hotel corridor may not work efficiently in a hospital ICU and a device meant for a chemical plant could be unsafe in a commercial kitchen. This is why engineers, safety managers and facility owners must understand which type of fire detector is ideal for each environment, based on risk levels, occupancy type, sensitivity needs and local fire codes. Modern detector manufacturers, including GST, offer a wide range of devices engineered for diverse applications. While each brand has its own strengths, the real decision lies in matching the right technology with the right setting rather than relying on generic “one-type-fits-all” solutions. This article will guide you through: Let’s begin. Why Different Buildings Need Different Types of Detectors Every building has unique fire risks. Hospitals are filled with oxygen cylinders and bedsheets. Hotels have kitchens, laundries and high footfall. Industrial plants handle chemicals, machinery and heavy electrical loads. Choosing a suitable detector depends on factors such as: 1. Fire Risk Type 2. Environmental Conditions 3. Occupant Sensitivity Hospitals need early detection with minimal disruption. Hotels need quiet environments without false alarms. Industrial sites prioritize robustness and hazard-compatible designs. 4. Compliance With Local Codes Fire norms for healthcare differ from hospitality and heavy industries. The detector choice must satisfy local authority requirements. This is why leading fire detection brands, including GST, offer multiple models, optical, thermal, multi-sensor and specialized detectors, so engineers can tailor solutions for each application without relying on generic options. Types of Fire Detectors: A Simple Breakdown To choose correctly, you must know how each detector works and where it is most effective. 1. Smoke Detectors Types Where They Work Best Limitations Modern detectors, including those available from advanced brands like GST, now incorporate improved optical chambers to reduce false alarms in typical hospitality and healthcare zones. 2. Heat Detectors Types Where They Work Best Limitations Heat detectors are reliable in environments where smoke is common and could trigger false alarms. 3. Multi-Sensor Detectors These detectors combine: Advantages Where They Work Best Many brands (GST included) offer multi-sensor detectors engineered to intelligently differentiate between real fire signatures and harmless aerosols. 4. Carbon Monoxide (CO) Fire Detectors These do not detect CO poisoning; they detect CO generated from a fire. Where They Work Best Limitations 5. Flame Detectors Types Where They Work Best Limitations These are specialty detectors used only in high-risk zones. 6. Gas Detectors Gas detectors are not fire detectors but are often part of fire safety systems. Where They Work Best Detector Recommendations for Different Facility Types Now let’s match building needs with detector categories. Best Detectors for Hospitals Hospitals require the fastest possible detection with the lowest disturbance. Critical areas like ICU, NICU and OT have stricter requirements. Recommended Detector Types 1. Optical Smoke Detectors Ideal for: Optical detectors in brands like GST often come with enhanced algorithms to reduce false alarms caused by disinfectants or aerosol sprays, common in hospitals. 2. Multi-Sensor Smoke + Heat Detectors Ideal for: These detectors provide: 3. Aspirating Smoke Detectors (ASD) Ideal for: This is because ASD: 4. Heat Detectors For: Best Detectors for Hotels Hotels face a variety of environments: guest rooms, kitchens, corridors, banquet halls and mechanical rooms. Recommended Detector Types 1. Multi-Sensor Detectors (Smoke + Heat) Best for: Hotels need detectors that: Modern multi-sensor detectors, including those from GST, use intelligent algorithms to distinguish real fire particles from harmless aerosols. 2. Optical Smoke Detectors Used for: These areas benefit from early detection without requiring the complexity of multi-sensor units. 3. Heat Detectors Used for: Heat detectors prevent false alarms from steam and cooking smoke. 4. CO Fire Detectors Used for: Hotels with underground parking should combine CO fire detectors with exhaust control systems. Best Detectors for Industrial Sites Industrial environments are the most complex due to: Recommended Detector Types 1. Heat Detectors For: Heat detectors withstand tough conditions where smoke detectors might fail. 2. Flame Detectors For: UV/IR or triple-IR flame detectors provide rapid detection even in dusty or large open spaces. 3. Gas Detectors For: 4. Optical Smoke Detectors (Industrial-Grade) Used in: Modern detectors from brands like GST are designed with anti-dust structures to operate effectively in light-industrial conditions. 5. Aspirating Detectors Used in: ASD ensures early fire detection, helping to prevent downtime in critical industrial operations. Common Mistakes to Avoid While Choosing Fire Detectors 1. Using the same detector type throughout a facility A hotel room and a boiler room cannot use the same device. Tailor choices per zone. 2. Ignoring environmental factors Heat, humidity, or dust can impair detector performance. 3. Not evaluating false alarm reduction features Modern detectors, including those by GST and other reputed brands, use digital algorithms to differentiate real fire from nuisances. 4. Installing detectors without compatibility checks If you use a specific brand panel, ensure the detectors are approved for that system. 5. Overlooking maintenance requirements Dirty environments require detectors with anti-dust design and easier maintenance. 6. Ignoring local fire code requirements Healthcare codes differ from industrial norms. Compliance is mandatory. Engineering Considerations 1. Response Time Hospitals: Need ultra-fastHotels: Fast but stableIndustries: Depends on zone 2. Sensitivity Level High sensitivity needed in: Moderate sensitivity for: Lower sensitivity for: 3. Redundancy Requirements Critical zones require: 4. Integration with Addressable Panels Today, most large buildings shift to addressable systems for: Choosing the right fire detector is not about selecting a brand first, it’s about selecting the right technology for the environment. Hospitals, hotels and industrial sites each have unique fire risks, occupancy patterns and environmental conditions. In general: Advanced detector lines offered by established manufacturers such as GST provide a wide range of options suitable for all these sectors. Their engineering depth ensures you can design systems that enhance safety without being dependent on promotional claims. A well-chosen detector not only saves lives but also reduces false alarms, maintenance downtime and long-term operational risks. The right selection today becomes the foundation of safer infrastructure tomorrow. Read

7 Ways Addressable Systems Save Money Over Conventional Systems

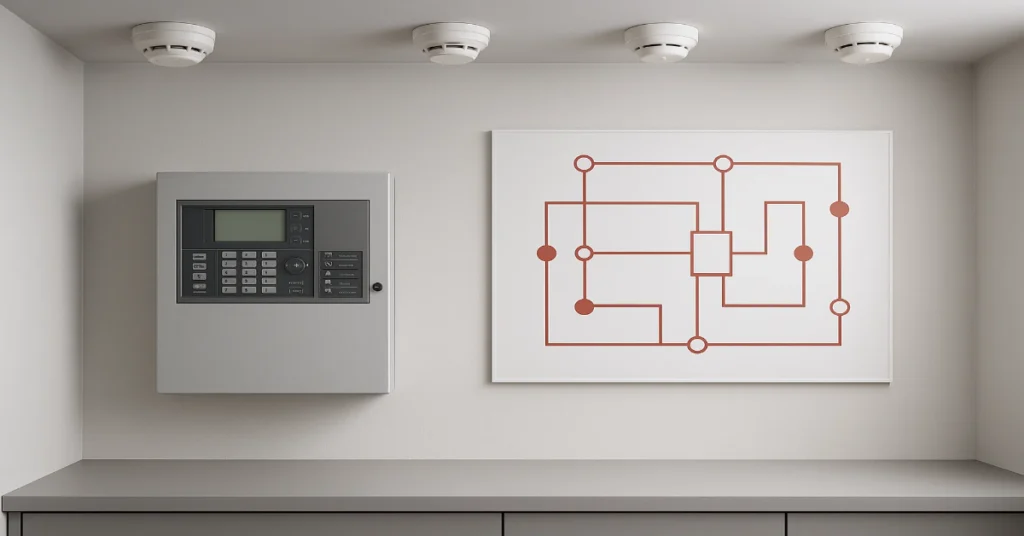

Fire safety is a non-negotiable part of any building’s infrastructure, whether it’s a hospital, hotel, commercial tower, industrial plant or educational campus. Yet, many organisations still struggle with the ongoing expenses related to fire alarm installation, maintenance, troubleshooting, upgrades and downtime. One of the most effective long-term financial decisions facility owners and engineers can make today is shifting from conventional fire alarm systems to addressable fire alarm systems. Addressable systems are widely recognised for delivering higher performance and better control. But an equally important advantage, especially from a facility management and procurement perspective, is cost efficiency. While the upfront investment may seem higher, the life-cycle cost of ownership is substantially lower and the savings continue to compound over time. This article explains seven powerful and practical ways addressable fire alarm systems help organisations save money. 1. Reduced Wiring Costs: One Loop vs Multiple Circuits In conventional systems, each zone requires separate wiring. As the building size increases, the complexity and cost of cabling multiply. Each floor or area may require its own circuit, significantly increasing installation expenditure. Addressable systems work differently. Instead of wiring each device individually to the control panel, all devices sit on a single communication loop. This results in: In multi-storey buildings, hotels, hospitals, large warehouses or campuses, these savings become dramatic. Addressable loops can cover long distances, meaning engineers avoid the complications of installing dozens of parallel circuits. Why This Saves Money Even though the devices used may be more advanced, the overall installation cost in many medium- and large-scale facilities is significantly lower compared to conventional systems. 2. Faster Fault Detection Minimises Downtime & Technicians’ Visits Conventional fire alarm systems only report a problem at the zone level. If a zone enters fault mode, technicians must search manually, sometimes checking dozens of devices across several rooms or floors. This leads to: Addressable systems solve this issue instantly. Every detector, module or device has a unique address, so the panel shows exactly which device has a problem. How This Results in Savings In facilities where downtime equals revenue loss, such as data centres, manufacturing units and hospitals, this alone can deliver significant financial benefit over the system’s lifespan. 3. Lower False Alarm–Related Losses False alarms are more than an inconvenience, they are expensive. They cause: Conventional systems struggle with distinguishing between smoke, dust, steam and environmental disturbances. They only relay zone-level alerts. Addressable systems, however, use advanced detection algorithms and offer device-level intelligence. Many models allow engineers to adjust sensitivity levels based on the environment. Cost Savings from Reduced False Alarms Over a span of 5-10 years, false-alarm avoidance alone can save organisations ** lakhs of rupees**. 4. Lower Maintenance & AMC Costs Due to Device-Level Monitoring With conventional systems, maintenance teams must physically inspect every detector at regular intervals. This manual checking increases AMC costs and consumes valuable time. Addressable systems continuously monitor and self-diagnose each device. Panels can show: This means maintenance becomes more predictive and efficient, reducing unnecessary labour hours. Savings Include Facility managers can plan maintenance without wasting time on guesswork. 5. Cheaper Long-Term Scalability & Expansion Buildings evolve. New floors get added. Industrial areas expand. Hotels renovate. Hospitals add departments. A system that was enough five years ago becomes insufficient today. Conventional systems struggle with expansion because: Addressable systems are built for long-term scalability. You can add new detectors or modules to the existing loop without redesigning entire circuits. Financial Advantages For buildings that expect future expansion, addressable systems provide unmatched lifecycle cost benefits. 6. Longer System Lifespan & Less Hardware Replacement Conventional panels and detectors rely on older technology and components often need replacement sooner due to limited diagnostic abilities. Dust buildup, ageing circuits and non-intelligent sensors degrade over time, often without detection. Addressable devices are designed with: This keeps the system healthier for longer and reduces premature replacement. This Reduces Long-Term Expenses Through A well-maintained addressable system often lasts 15+ years with minimal operational cost. 7. Better Energy Efficiency & Lower Operational Costs Addressable systems are engineered to be power-efficient. Even with advanced intelligence, they require less current compared to many conventional installations that depend on multiple circuits and higher load per zone. This contributes to long-term savings through: In large commercial, industrial or institutional facilities, the reduction in power consumption is a meaningful cost advantage that compounds annually. Real-World Examples of Savings Hotels Hotels using addressable systems reduce operational disruption, avoid false alarms and minimise maintenance visits, improving guest satisfaction and operational efficiency. Hospitals Addressable systems help maintain sensitive environments (ICUs, labs, OTs) with fewer false alarms and faster detection accuracy, saving money and protecting patient safety. Industries Manufacturing units benefit from predictive maintenance, fewer line stoppages and reduced power consumption. Commercial Buildings Malls, offices and IT parks reduce facility management efforts, wiring complexity and long-term operational costs. How Addressable Systems Deliver Better ROI When facilities move from conventional to addressable systems, they experience savings in: Even though the initial investment is slightly higher, the 5-year and 10-year total cost of ownership (TCO) is significantly lower. Addressable technology also aligns with modern building codes, smart infrastructure, future-proof planning and digital facility management practices. Note: Choosing between conventional and addressable fire alarm systems isn’t just a technical decision, it’s a financial one. Addressable systems provide clear and measurable savings across installation, operation, maintenance, scalability and long-term ownership. For organisations looking to optimise both safety and cost-effectiveness, addressable systems offer a smarter, more sustainable and more economical solution. They deliver enhanced reliability, greater control and long-term value without adding complexity. In the modern era of intelligent buildings and advanced life safety standards, an addressable fire alarm system is not just an upgrade, it’s an investment that pays for itself over time. Read Also: The Real Reason Your Fire Alarm System Has Frequent False Alarms Read Also: Why Addressable Panels Offer Higher ROI Than Conventional Panels