Fire protection engineering has evolved rapidly over the past decade. Today, industries, commercial complexes and high-rise buildings expect fire alarm systems that are not only reliable but also intelligent, scalable and compliant with the latest codes. This demand has intensified the debate between addressable and conventional fire alarm panels.

From an engineering perspective, these two systems follow the same core purpose, detecting fire early and notifying occupants. However, their architecture, communication method, design workflow, maintenance cost and long-term scalability differ significantly.

This article provides a deep engineering comparison, explaining how each system works, where it fits best and why many engineers prefer modern addressable systems, especially in growing markets like India.

Understanding the Core Architecture

To evaluate both systems, engineers first look at how the devices communicate with the panel.

Conventional Panels: Zone-Based Architecture

A gst conventional fire alarm system divides the building into zones. Each zone connects several detectors and call points via parallel wiring. When an alarm triggers, the panel displays the specific zone but not the exact device.

Characteristics:

- Devices are connected in radial circuits.

- Supports simple signal transmission.

- Limited data communication.

- Zone-based identification (not device-specific).

- Best suited for small and low-complexity layouts.

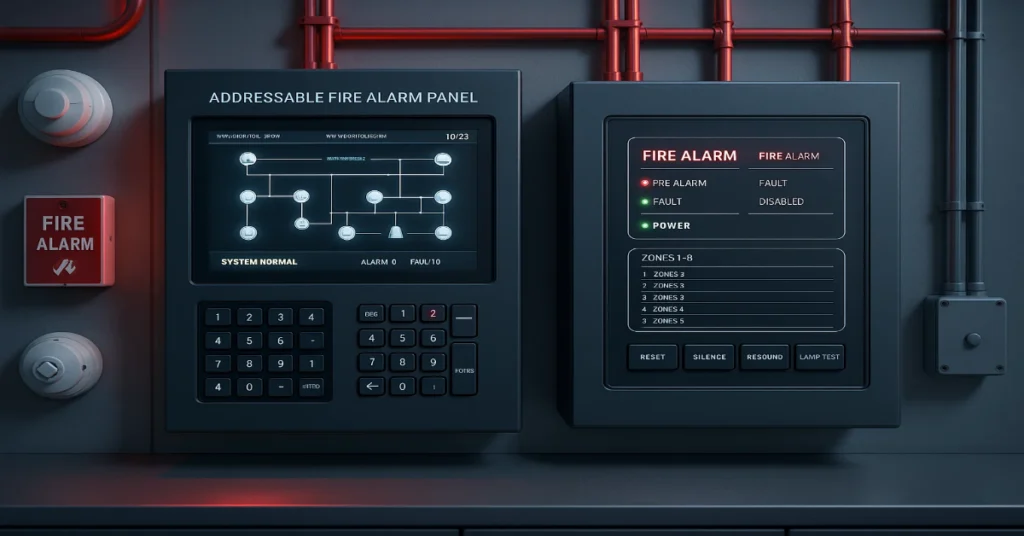

Addressable Panels: Device-Specific Intelligent Architecture

An gst addressable fire alarm panel assigns unique digital addresses to each device. This enables two-way communication between the panel and every detector or module. The panel can identify the exact device, its condition and even pre-alarm data.

Characteristics:

- Loop-based wiring topology.

- Each device has an electronic address.

- Advanced multi-level communication.

- Precise identification of alarms, faults and maintenance needs.

- Highly scalable for large buildings.

Engineering Comparison: How Each System Performs

Engineers evaluate fire alarm panels on real-world parameters that directly impact safety, cost, maintenance and code compliance. Below is a clear comparison.

Wiring Design and Installation

Conventional System Wiring

The wiring topology is relatively simple but rigid:

- Each zone requires a separate pair of cables.

- Sounder circuits require separate cabling.

- More zones = more wiring pathways.

- Expansion becomes complicated because adding a zone means adding cables, breakers and panel upgrades.

Engineer’s Note:

This increases both material cost and labour cost, especially for multi-floor buildings.

Addressable System Wiring

Addressable panels use loop wiring, which allows many devices on a single circuit.

- A single loop can support detectors, modules and sounders.

- Loop isolators offer built-in redundancy.

- Wiring is flexible and adaptable to complex layouts.

- Expansion is easy, just add devices to the loop.

Engineering Advantage:

Up to 30–40% cable reduction is common in large projects, lowering overall cost of installation.

Accuracy of Fire Detection

Conventional Detection Accuracy

Because several detectors share the same zone, the system can only indicate that a “Zone 3 Alarm” occurred. Engineers then need to manually inspect:

- Which detector triggered

- Whether it was a false alarm

- The exact location of the threat

This delays response during critical seconds.

Addressable Detection Accuracy

Addressable systems pinpoint the exact device and its address:

- “Detector 34 – Level 5 – Server Room”

- “Heat Detector – High Temperature Warning”

- “Smoke Detector – Pre-Alarm Threshold Passed”

Modern addressable panels even support environmental drift compensation, reducing false alarms.

Why Engineers Prefer This:

Clear localization drastically improves evacuation decisions and fire-fighting strategy.

System Reliability and Fault Management

Conventional Panels

Fault notifications are limited:

- Only zone-level faults are displayed.

- Short circuits may disable the entire zone.

- Troubleshooting is time-consuming and manual.

Addressable Panels

Addressable panels provide deep system diagnostics:

- Device-level fault reporting

- Log history and event records

- Short-circuit isolation and auto-recovery

- Real-time device health monitoring

If a cable cuts, isolators localize the problem and the rest of the loop remains operational.

Engineering Impact:

Improves uptime and reduces maintenance cycles significantly.

Scalability and Future-Proofing

Conventional Panels

Scaling is difficult:

- More zones = more wiring, conduits and panel upgrades

- High chance of design changes during future expansion

- Limited support for intelligent devices

Suitable only for small projects such as:

- Small shops

- Low-rise buildings

- Small warehouses

Addressable Panels

Addressable panels are built for future flexibility:

- Add devices without major rewiring

- Supports large networks of buildings

- Ideal for industrial campuses, malls, hospitals, IT parks

- Can integrate with BMS, access control, HVAC, aspirating systems

Modern brands like GST offer addressable systems with modular loop expansion and communication cards, making upgrades smooth and cost-efficient.

Maintenance and Life-Cycle Cost

Conventional System Maintenance

Maintenance is manual and time-consuming:

- Detector testing per zone

- Tracking false alarms manually

- Replacing zone modules and wiring faults

This increases long-term cost.

Addressable System Maintenance

Addressable systems are engineered for efficient maintenance:

- Device health reports

- Drift analysis

- Auto-learning algorithms

- History logs

- Faster troubleshooting

Over a 10-year cycle, an addressable system often delivers 30-50% lower operational cost due to reduced downtime and maintenance hours.

Fire Response Strategy and Evacuation Management

Conventional Panels

Conventional systems do not provide advanced evacuation logic:

- Only basic alarm triggering

- No selective alerting

- Limited integration with automated systems

Addressable Panels

Modern addressable panels support sophisticated evacuation management:

- Selective evacuation of affected floors

- Integration with emergency lighting and voice alarms

- Multi-stage alarm logic

- Real-time fire progression tracking

This is essential for high-density buildings like IT parks, malls, hotels and airports.

Integration with Modern Safety Ecosystem

Conventional Panels

Integration possibilities are limited:

- Only dry contacts

- No digital communication

- Basic third-party interface

Addressable Panels

Engineers appreciate the seamless integrations:

- BMS

- HVAC shutdown

- Fire suppression system activation

- Lift control

- Access control release

- Emergency communication systems

This creates a smarter safety ecosystem.

Cost Comparison: Initial vs Life Cycle

Initial Cost

Conventional panels have:

- Lower upfront cost

- Lower device cost

- Higher wiring and labour cost for large buildings

Addressable panels have:

- Higher panel and device cost

- Lower cabling cost

- Lower installation complexity

Life Cycle Cost

When engineers evaluate cost across 10–15 years, addressable systems are more economical due to:

- Lower maintenance cost

- Lower downtime

- Scalable architecture

- Accurate fault identification

- Fewer service visits

Compliance with Indian and International Standards

Conventional Panels

Conventional systems are compliant with:

- IS 3218

- Basic NBC requirements

But they may not meet advanced safety requirements for:

- High-rise buildings

- Smart buildings

- Large industrial sites

Addressable Panels

Addressable systems align with:

- IS 2189

- NBC 2016 (and upcoming revisions)

- NFPA 72

- IEC standards

- Most global industrial safety norms

With 2025 updates focusing heavily on smart systems, addressable panels are future-ready for compliance.

From an Engineer’s Perspective: Which One Should You Choose?

Choose Conventional If:

- The building is small.

- Budget is extremely limited.

- There are fewer than 20–40 devices.

- You don’t need device-level identification.

Choose Addressable If:

- You want precise device-level detection.

- The project is medium to large scale.

- Long-term cost and maintenance matter.

- You need future expansion capability.

- Integration with BMS/IoT systems is required.

- You want compliance with modern codes.

In 2025, more than 70% of medium and large commercial projects in India (as per industry observations) have shifted to addressable panels due to greater reliability and future readiness.

Why Many Engineers Prefer GST Addressable Panels

GST is widely adopted across India because:

- It offers fully addressable, EN54-certified systems.

- Panels are scalable from small offices to mega projects.

- It provides excellent loop capacity and stability.

- Detectors use intelligent algorithms to reduce false alarms.

- Easy integration with third-party systems.

- Strong after-sales support in most Indian cities.

This makes GST a trusted choice for consultants and integrators.

What Matters Most in 2025?

From an engineering perspective, the choice between addressable and conventional fire alarm panels depends on:

- Building size

- Layout complexity

- Expansion plans

- Budget

- Required response speed

- Compliance needs

Conventional systems still serve small spaces well, but addressable panels have become the engineering standard for modern infrastructure. They offer precision, scalability, lower life-cycle cost and powerful integration capabilities, making them the smarter long-term choice.

A well-designed addressable system ensures faster detection, quicker evacuation and higher compliance, ultimately contributing to a safer, smarter, more future-ready building.

Read Also: Why Fire Alarm Systems Are the First Layer of Industrial Safety

Read Also: Where to Buy Original GST Addressable Fire Alarm Panels in India