Buy GST Addressable Fire Alarm Panel in Delhi NCR – Best Price & Fast Delivery

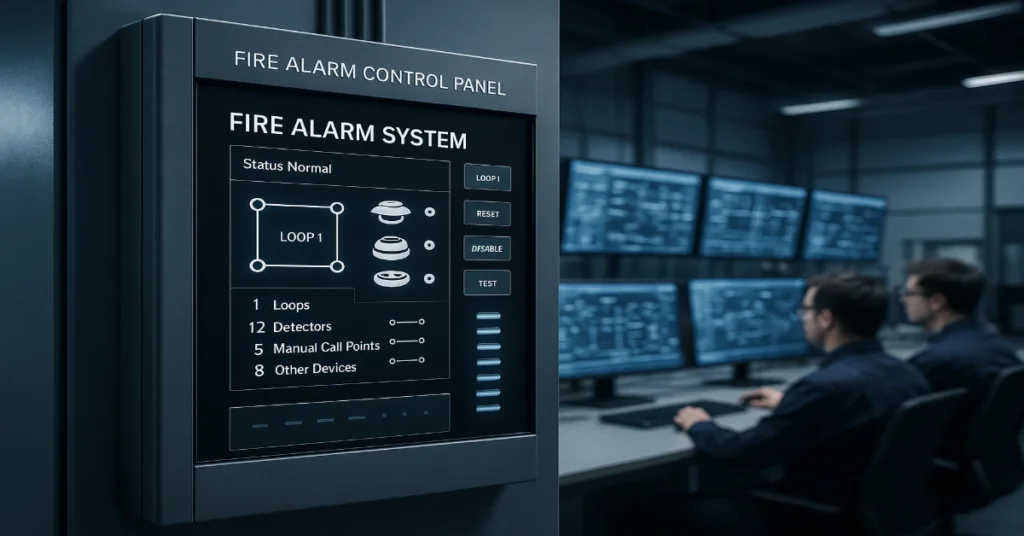

Ensuring the safety of industrial, commercial and residential facilities is a top priority in today’s rapidly growing urban areas. One of the most effective ways to protect life and property is by installing a reliable GST Addressable Fire Alarm Panel. With their advanced technology, these systems not only detect fire quickly but also provide precise information about the location of the hazard, enabling faster response times and minimizing potential damage. If you are looking to buy GST addressable fire alarm panels in Delhi NCR, INNEXON is a trusted authorized dealer offering the best prices and fast delivery. As a dedicated distributor, INNEXON ensures that you get genuine GST products without the hassles of installation or maintenance services. What is a GST Addressable Fire Alarm Panel? A GST addressable fire alarm panel is an intelligent system designed to detect fire and smoke hazards efficiently. Unlike conventional fire alarm systems, where all detectors trigger the same alarm, addressable systems identify the exact location of the fire. This feature is crucial for large-scale buildings and industrial setups, as it allows for targeted emergency responses. Key benefits of GST addressable panels include: Types of GST Addressable Fire Alarm Panels Available At INNEXON, we offer a wide range of GST addressable fire alarm panels suitable for different applications: 1. GST-IFP4E Advanced Touchscreen Addressable Fire Alarm Control Panel 2. GST-IFP8 Addressable Fire Alarm Control Panel 3. GST100 Series – Compact Intelligent Addressable Fire Alarm Control Panel 4. GST200N Series – Intelligent Addressable Fire Alarm Control Panel Why Choose GST Addressable Panels in Delhi NCR? Delhi NCR is home to a wide range of industrial, commercial and residential facilities. Fire safety is a critical concern due to high population density and complex building structures. Choosing GST addressable fire alarm panels ensures: INNEXON – Authorized GST Dealer in Delhi NCR As a trusted authorized distributor of GST fire alarm products, INNEXON provides: This ensures clients receive authentic, reliable fire safety products without confusion about service responsibilities. Get Quotation Now by Contacting Us! Email at: marketing@innxeon.com Contact Number: +91 93117 10611 Features of GST Addressable Fire Alarm Panels GST addressable panels come with a range of advanced features: How to Buy GST Addressable Fire Alarm Panels in Delhi NCR Buying GST panels is simple with INNEXON: Tips for Choosing the Right Fire Alarm Panel When selecting a GST addressable fire alarm panel, consider: Why GST Panels are the Best Choice For businesses and facility managers in Delhi NCR, investing in a GST addressable fire alarm panel is a smart decision. It ensures early detection, precise location identification and improved safety for both people and property. INNEXON, as a trusted authorized dealer, provides genuine GST panels at competitive prices with fast delivery, making it easy to secure your facility’s fire safety. Protect your facility, reduce risks and ensure peace of mind with GST addressable fire alarm panels. Read Also: Buy GST Addressable Fire Alarm Panel for Industrial & Commercial Buildings Read Also: Best GST Addressable Heat and Smoke Detectors for Industrial Warehouses

Best GST Addressable Heat and Smoke Detectors for Industrial Warehouses

Industrial warehouses face heavy fire risks due to high ceilings, large storage areas, machinery, packaging materials and varied environmental conditions. In such settings, fire detection has to be fast, precise and scalable. GST addressable fire alarm systems stand out because each device on the loop has a unique address, allowing instant pinpointing of alarm or fault locations. This article explains the best GST addressable detectors and devices suitable for industrial warehouses, along with features, benefits, installation insights and practical selection tips. Why GST Addressable Devices are Ideal for Warehouses Warehouses need advanced fire safety solutions that do more than detect fire. GST addressable technology enables smarter monitoring, reduced wiring and faster response. Advantages: With these capabilities, GST addressable systems support both safety and operational continuity in industrial environments. Core Device Categories for Warehouses To build a reliable fire system, multiple addressable devices work together in a loop. Here’s a clear breakdown of what matters most: 1. Photoelectric (Optical) Smoke Detectors Best for: Aisles, open storage zones, areas where smoke appears early. Features: Popular Example Models: These detectors are ideal for smoldering fires and general smoke detection across wide floor areas. 2. Heat and Rate-of-Rise Detectors Best for: High ceilings, dusty or hot areas, machinery zones. Features: Popular Example Models: These are especially useful where smoke detectors may trigger false alarms due to dust or airflow. 3. Multi-Sensor (Combination) Detectors Best for: Areas with complex fire patterns. These detectors combine smoke and heat sensing to reduce false alarms while improving accuracy. A common example is the dual-function DI-9101E. 4. Addressable Sounder and Beacon Bases Best for: On-site evacuation and visual alerts. Features: Example Models: These devices allow alerting and detection from the same mounting point. 5. Input/Output Modules & Isolators Best for: Integrating external systems like HVAC, sprinklers, fire doors. Features: Example Devices: These modules enable custom control of other safety equipment during a fire event. 6. Addressable Fire Alarm Panels All devices connect back to a control panel that handles monitoring, logic and communication. Best-In-Class Features: Example Panels: These panels allow large-scale loop configurations suitable for warehouse layouts. Best Practices for Warehouse Implementation Correct Detector Placement Environmental Adaptation Logical Zoning Maintenance Planning Integration with Safety Equipment Common Challenges and How to Solve Them Challenge Solution High ceiling smoke delay Use beam detectors or dense layouts Dust or fumes Use heat or multi-sensor detectors Strong airflow Avoid detector placement near vents False alarms Configure thresholds and combine sensors Loop faults Use isolators to localize problems Future growth Leave spare addresses and expansion slots Quick Selection Summary Category Best Use Recommended Device Types Smoke Detection General warehouse zones DI-9102E, I-9102 Heat Detection Dusty/hot areas DI-9103E, DI-9101E Multi-Sensor Mixed risk zones DI-9101E Audible Alerts Evacuation paths DI-9405, DI-9406 System Integration Control & monitoring DI-9300E, DI-9301E, DI-9305E, DC-9503E Control Panel Full system operation GST-IFP4E, GST200N Installation to Commissioning Roadmap For industrial warehouses, fire detection needs to be intelligent, adaptable and scalable. GST addressable detectors and devices provide individual addressing, advanced logic, automatic diagnostics and loop-based communication. By combining photoelectric detectors, heat sensors, combo devices, addressable sounders, I/O modules, isolators and capable control panels, warehouses can achieve fast detection, fewer false alarms and reliable emergency response. Read Also: How Much Can You Save by Switching to GST Addressable Fire Alarm Systems? Read Also: Buy GST Addressable Fire Alarm Panel for Industrial & Commercial Buildings

Buy GST Addressable Fire Alarm Panel for Industrial & Commercial Buildings

Fire safety is not optional, it is a legal requirement and a moral responsibility for every industrial and commercial building owner. Among various fire detection solutions, GST addressable fire alarm panels have emerged as a preferred choice for factories, warehouses, malls, hospitals, tech parks, manufacturing facilities, offices, airports, refineries, logistics hubs and high-rise commercial complexes. These systems offer reliability, advanced monitoring and early detection capabilities that minimize damage and protect lives. If you’re planning to buy a GST addressable fire alarm panel, this detailed guide will help you understand why it’s the right investment, what features to look for, how it benefits both industrial and commercial environments and how to choose the ideal system for your building. Why Choose a GST Addressable Fire Alarm Panel? GST (Gulf Security Technology) is a globally trusted brand in the fire detection industry. Their addressable systems are designed to offer intelligent, location-specific alerts, reduce false alarms and support large infrastructure projects seamlessly. Here are the top reasons to invest in GST addressable fire alarm panels: 1. Precise Fire Detection & Location Identification Unlike conventional panels, addressable systems assign a unique address to each connected device. When a detector senses smoke, gas or heat, the panel displays: This rapid identification helps security and safety teams respond immediately. 2. Scalable for Large and Multi-Site Buildings Industrial and commercial buildings often require extended loops and multi-zone monitoring. GST panels can support: This scalability makes it ideal for warehouses, data centres, malls and campuses. 3. Fewer False Alarms Traditional fire alarms often generate nuisance alerts due to dust, humidity, machinery or temperature changes. Addressable fire alarm systems use intelligent algorithms and sensor differentiation, resulting in near-zero false alarms. 4. Easy Maintenance and Remote Monitoring GST panels support: This reduces maintenance time and increases system uptime. 5. Compliance with National & International Safety Codes GST systems meet major fire safety standards, including: Whether you’re planning new construction or upgrading, compliance becomes easier with GST. Benefits for Industrial Buildings Industrial sites are prone to high fire risks caused by heavy machinery, flammable chemicals, electrical loads and continuous operations. Here’s how GST addressable panels enhance their safety: Benefits for Commercial Buildings Commercial infrastructures such as IT parks, malls, hospitals, hotels, office towers, airports and educational institutions demand seamless evacuation and multi-floor fire safety. GST addressable fire alarm panels offer: Types of GST Addressable Fire Alarm Panels Here’s an overview of the most commonly used GST models in industries and commercial properties: GST200N GST100 GST5000 or GST9000 These panels can be paired with GST addressable detectors, heat and smoke sensors, sounders, call points and modules for complete protection. Core Components of a GST Addressable Alarm System When buying the system, these components are typically required: Selecting components according to your site layout ensures better performance and compliance. Factors to Consider Before Buying GST Addressable Fire Panels To choose the right model, consider: 1. Building Type and Size Industrial warehouses need wider coverage and more loops than retail stores or smaller commercial spaces. Always match panel capacity to infrastructure. 2. Fire Safety Regulations Local fire norms and insurance requirements define system specifications. GST systems are certified and compliant, making approvals easier. 3. Number of Detection Devices Panels have address limits per loop. Accurate device count helps select the right panel model. 4. Expansion and Scalability If you expect future expansions, pick a panel that supports additional loops or networking. 5. Integrated Safety Systems Ensure the panel supports integration with sprinklers, HVAC, elevators, PA systems and BMS. 6. Vendor Support and Warranty Choose certified GST dealers to ensure installation quality, annual maintenance contracts (AMC) and genuine spares. Installation and Commissioning Best Practices To maximize performance, follow these guidelines: GST systems are known for supports diagnostics, making maintenance easier for contractors and in-house facility managers. Cost Insights: What to Expect Pricing depends on: Even though addressable systems cost more initially, long-term ROI is higher due to low false alarms, better coverage and lower maintenance. Where to Buy GST Addressable Fire Alarm Panels? Always buy from authorized suppliers or GST-certified system integrators to ensure: Many suppliers offer end-to-end solutions including design, installation, programming, integration and inspection compliance. Future-Ready Technology & Smart Integrations GST addressable panels are future-proof and compatible with: This makes them ideal for modern industrial automation and commercial infrastructure management. If you’re responsible for safety in an industrial or commercial building, buying a GST addressable fire alarm panel is a smart and future-ready decision. It enhances fire safety, supports compliance, minimizes false alarms, improves response time and ensures long-term protection for people and property. Whether you’re retrofitting an old facility or outfitting a new structure, GST panels deliver superior performance, advanced monitoring and scalable configuration capabilities suitable for buildings of every size. Read Also: How GST Fire Panels Ensure Faster Detection and Zero False Alarms in Complex Facilities Read Also: How Much Can You Save by Switching to GST Addressable Fire Alarm Systems?

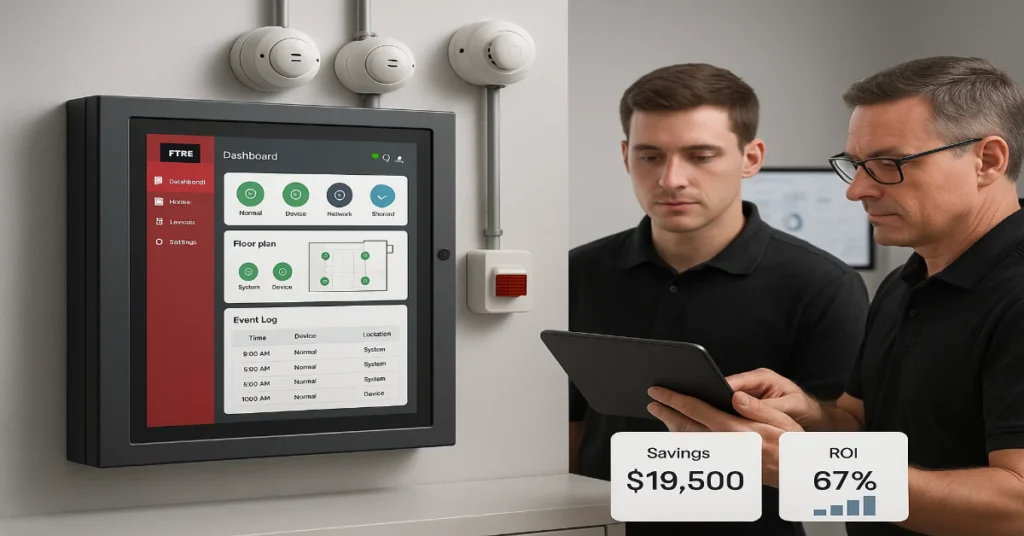

How Much Can You Save by Switching to GST Addressable Fire Alarm Systems?

Fire safety isn’t just about compliance, it’s about long-term cost efficiency, system reliability and operational convenience. Contractors, builders and system integrators are facing increasing pressure to offer solutions that deliver high returns while reducing maintenance and installation overheads. That’s exactly where GST addressable fire alarm systems outshine conventional options. In this detailed breakdown, you’ll discover how switching to GST addressable systems can generate savings across installation, maintenance, scalability, manpower and false alarm reduction. By the end, you’ll have a clear picture of the ROI contractors can expect, whether upgrading from a conventional system or choosing GST for new projects. 1. Lower Installation Costs with Reduced Cabling One of the biggest savings for contractors comes during the installation phase. Conventional Systems: GST Addressable Systems: Average Savings:Contractors report up to 25-40% reduction in cabling costs per project depending on layout size. For a 10,000 sq. ft. commercial project: Direct Savings: ₹80,000 to ₹1.2 lakh per project Less cable also means fewer labor hours and faster handover, which directly boosts ROI. 2. Faster Commissioning and System Configuration Conventional panels require manual device mapping and zone allocation. Addressable GST systems simplify commissioning with: Time Saved:On average, contractors save 30–50% of commissioning time. If a conventional setup takes 5 days, a GST addressable system can be commissioned in 2.5–3 days. For contractors juggling multiple projects, faster commissioning = reduced labor costs + more billable projects annually. 3. Reduced False Alarm Costs False alarms are more than just an annoyance, they drain resources and damage credibility. Conventional Fire Alarm Systems: GST Addressable Systems: Impact on ROI: Estimated Savings:False alarm–related service calls drop by 60–80%, saving both time and money. 4. Lower Maintenance and Service Costs GST addressable fire alarm systems enable: Cost Comparison (Annual) Expense Head Conventional GST Addressable Service Technician Visits 6–8/year 2–3/year Maintenance Cost ₹80k–₹1 lakh ₹35k–₹50k Downtime Higher Negligible Estimated Yearly Savings: ₹40,000–₹50,000 Over five years, maintenance savings alone can exceed ₹2–2.5 lakh for a mid-sized facility. 5. Scalable Upgrades = Long-Term ROI When clients expand or renovate, contractors often face the headache of rewiring or reconfiguring traditional panels. GST addressable panels eliminate that challenge: Savings on upgrades can reach ₹1-1.5 lakh over the system’s lifecycle. Contractors win through faster turnaround, while clients appreciate long-term cost predictability. 6. Fewer Manpower Hours = More Profit Labor expenses make up nearly 50% of fire protection projects. With GST addressable systems: Example Scenario:For a 20,000 sq. ft. facility Task Conventional GST Addressable Labor Hours 200–220 hrs 110–130 hrs Manpower Cost ₹2.2 lakh ₹1.3 lakh Direct Saving: ₹80,000–₹90,000 Reduced manual labor allows contractors to complete more jobs in a year, boosting revenue without increasing workforce. 7. Better Margins for AMC Contracts GST addressable systems are designed for low-maintenance performance, allowing contractors to: If AMC expenses drop by 40%, but pricing remains stable, contractors secure higher recurring profits. Over a 5-year AMC contract, this can add up to ₹1–2 lakh profit per site. 8. Compliance and Approvals at Lower Cost GST addressable systems are certified to global and regional safety standards like: This ensures: Contractors avoid last-minute replacements or redesigns, saving weeks of delay. 9. Remote Monitoring Reduces Site Visits With optional networking and app-based supervision, GST systems allow: Contractors can manage multiple client sites with one team, cutting manpower requirements by 30–40%. 10. ROI Snapshot: Real Cost-Benefit Overview Let’s consolidate the potential savings per mid-sized commercial installation (15,000–20,000 sq. ft.): Cost Component Avg. Savings Cabling & Wiring ₹1,00,000 Commissioning Time ₹40,000 False Alarm Management ₹50,000 Annual Maintenance (5 yrs) ₹2,25,000 Manpower Reduction ₹80,000 AMC Margin Boost ₹1,50,000 Upgrade Flexibility ₹1,00,000 Total Estimated Savings Over 5 Years:₹7,00,000 – ₹8,50,000 per site Even if GST addressable systems cost 15–20% more upfront, the savings recover that cost in 12–18 months, after which the system turns into pure profit for the contractor and value for the client. Contractor Reputation and Repeat Business Switching to GST addressable systems helps contractors: In competitive B2B markets, efficiency + reliability = repeat success. Why Contractors Are Making the Switch Now Here’s what makes GST the go-to option for MEP firms, EPC contractors, fire integrators and industrial facility managers: High ROI, Low Risk, Fast Payback If you’re still using conventional fire alarm systems, every new installation is costing you more time, more manpower and more money than necessary. By shifting to GST addressable fire alarm systems, contractors can: ROI Range: The numbers speak for themselves: switching to GST (Gulf Security Technology) isn’t an upgrade, it’s a strategic business move. Read Also: 5 Built-in Features That Make GST Addressable Fire Alarm Panels Engineers’ First Choice Read Also: How GST Fire Panels Ensure Faster Detection and Zero False Alarms in Complex Facilities

How GST Fire Panels Ensure Faster Detection and Zero False Alarms in Complex Facilities

Fire safety in industrial and commercial environments requires more than just basic alarm systems. As facilities grow more complex with multiple floors, hazardous zones, data centres, manufacturing units and utility areas, the need for intelligent detection becomes crucial. This is where GST addressable fire panels have emerged as a top choice among engineers, system integrators and safety consultants. These panels not only ensure faster detection but also minimize or in many cases eliminate false alarms, which can be a major challenge in large facilities. In this article, you’ll learn how GST panels achieve this level of precision, reliability and performance while staying compliant with international safety standards. Why Fast Detection and Zero False Alarms Matter In high-risk environments like power plants, IT parks, refineries, logistics hubs and manufacturing units, fire detection time directly impacts safety, business continuity and asset protection. A delay of even 30 seconds can cause: Similarly, false alarms trigger: GST fire panels tackle both issues at the root using smart detection mechanisms, software-driven logic and reliable communication. What Makes GST Panels Faster and More Accurate? GST panels combine addressable technology, intelligent sensors, powerful processing and adaptive programming. Let’s break down how these features contribute to rapid detection and zero false alarms. 1. Addressable Technology for Precision Monitoring Unlike conventional panels that monitor zones, GST addressable panels detect the exact device that triggered the signal. Benefits: When a detector on loop 1, address 15 activates, the control panel immediately identifies it and displays it on the screen or control software. This speeds up response by minutes which can be lifesaving in critical environments. 2. Advanced Signal Processing for Faster Detection GST panels use multi-criteria detection and digital communication to assess fire conditions accurately. Their detectors analyze: The system uses internal algorithms to determine whether the data fits a real threat or a non-fire condition. Result: 3. Intelligent False Alarm Management False alarms often come from dust, steam, welding, cooking smoke or temperature changes. GST devices are engineered to ignore such interferences using: When a signal looks suspicious, the system validates it through multiple parameters before triggering evacuation procedures. 4. Loop Isolation and Smart Communication GST panels use fault-tolerant loops with isolators. If a short circuit or open circuit occurs in one section, the communication continues through alternate paths. Advantages: This feature not only prevents communication delays but also ensures accurate signals from detectors. 5. Programmable Sensitivity for Different Areas A complex facility may have clean rooms, industrial kitchens, underground parking and electrical rooms. Each area demands a different level of sensitivity. GST panels allow: This prevents detectors from overreacting in environments where minor particulates are normal. 6. Two-Stage Verification Logic To prevent false evacuation, GST panels often use pre-alarm logic: This double layer makes unwanted alarms nearly impossible. 7. Integration with BMS, HVAC and Fire Suppression GST addressable panels connect with: During real fire conditions, the panel: During false signals, it holds until verification, saving downtime and chaos. 8. Real-Time Remote Monitoring GST fire alarm panels can connect to monitoring software or SCADA systems. When an event occurs, the command center receives: Security teams can assess and respond immediately, even before an on-site team arrives. 9. Self-Diagnostics and Predictive Maintenance GST devices continuously monitor their own health. The panel alerts integrators about: This allows early servicing and eliminates sudden false alarm triggers. 10. Compliance with Global Standards GST panels meet a range of international certifications: These standards demand high performance in both detection accuracy and alarm reliability. Real-World Use Cases: Where GST Solves Critical Challenges How GST Panels Improve Response Time Here’s how speed is achieved without compromising accuracy: Feature Impact on Detection Time Addressable loops Real-time communication Digital protocols Faster signal transfer Programmable logic Instant decision-making Remote monitoring Instant alert to control room Device-level pinpointing Faster team dispatch Even in complex buildings with 1,000+ devices, the system takes less than 3 seconds to identify and display the event. Why False Alarms Are Almost Zero with GST GST’s anti-false alarm capabilities come from: These features make it difficult for non-fire elements to trigger the system. Benefits for Facility Managers and Engineers Choosing GST addressable panels delivers: False alarm reduction alone can save thousands of man-hours every year in large facilities. Installation Flexibility in Complex Buildings GST systems support: This makes them ideal for complex sites like: Remote Troubleshooting & Maintenance Alerts With GST’s networking capabilities, technicians can: This cuts down unnecessary site visits and false signals. Cost Advantage Over Time While GST panels may initially cost more than basic conventional systems, the long-term savings are significant due to: Total cost of ownership becomes much lower across 5–10 years. Building Trust with Occupants and Authorities Zero false alarms ensures: Complex facilities often face legal scrutiny, and GST panels make certifications easier to maintain. GST addressable fire panels are designed to meet the challenges of complex, high-risk and high-traffic environments. They combine intelligence, automation, accuracy and reliability to ensure fast detection and elimination of false alarms. If you’re an engineer, facility manager or system integrator working with large campuses or industrial plants, GST addressable fire panels offer: By investing in this technology, organizations not only protect assets and people but also gain operational stability and peace of mind. Read Also: Why Contractors Prefer GST Addressable Fire Alarm Panels Read Also: Top 5 Reasons Engineers Choose GST Addressable Fire Alarm Panels

5 Built-in Features That Make GST Addressable Fire Alarm Panels Engineers’ First Choice

In the industrial safety domain, fire detection and alarm systems play a crucial role in safeguarding lives, equipment and infrastructure. Engineers, facility managers and system integrators constantly seek reliable, intelligent and compliant solutions that simplify installation, improve response time and ensure long-term dependability. Among various brands in the market, GST Addressable Fire Alarm Panels stand out as a preferred choice for engineers worldwide. Known for their smart design, scalability and built-in intelligence, GST panels have proven themselves across sectors from manufacturing plants and refineries to data centers and commercial buildings. This article explores the five built-in features that make GST Addressable Fire Alarm Panels the first choice of engineers for complex fire protection projects. 1. Intelligent Addressable Detection System The first and most significant feature that distinguishes GST panels is their intelligent addressable detection capability. Unlike conventional fire alarm systems that trigger general zone alarms, GST Addressable Fire Panels communicate with each connected device, detectors, call points, modules and sounders, using digital signaling and unique addresses. Why Engineers Prefer It Example Use Case In a large industrial plant with multiple zones, the GST system enables engineers to monitor thousands of devices through a single panel interface. This precise detection helps in fast evacuation and targeted firefighting, preventing major operational losses. 2. Built-in Loop Communication and Networking Flexibility GST panels are designed with advanced loop communication protocols, allowing seamless connectivity between field devices and the control panel. This communication is the backbone of a reliable addressable fire system. Key Benefits Why It Matters for Engineers Loop-based networking ensures faster installation, less cabling and reliable long-distance communication, crucial for multi-building or high-rise projects. The flexibility to configure, expand, or integrate makes GST panels ideal for industrial, commercial and infrastructure-grade applications. 3. Integrated Event Logging and Real-Time Monitoring Another feature that engineers appreciate is the built-in event logging and real-time system monitoring capabilities of GST panels. What It Offers Benefits for Engineering Teams In environments like hospitals, data centres or industrial plants, this feature ensures engineers always have access to real-time insights, enabling quick decision-making and compliance reporting. 4. Seamless Integration with Building Management and Other Safety Systems Modern fire protection requires more than standalone alarms. It demands system integration. GST Addressable Fire Panels excel in seamless interoperability with Building Management Systems (BMS), Public Address (PA) and Access Control Systems. Integration Capabilities Why Integration Matters Integration allows centralized control, reduces human intervention and ensures coordinated emergency responses.For example, in a smart warehouse, when a fire alarm is triggered, the GST panel can automatically shut down ventilation, unlock emergency exits and trigger evacuation announcements, all in real-time. Such interoperability makes GST panels a preferred choice for system designers focused on smart, automated safety solutions. 5. Compliance, Reliability and Global Certifications Engineers value reliability and compliance above all else and GST Addressable Fire Alarm Panels deliver both. Certifications That Ensure Quality GST panels are certified and tested to meet international fire safety standards, including: Built-in Reliability Features Why Compliance Drives Engineer Confidence These certifications guarantee that GST panels not only meet local fire codes but also align with global industrial standards. For engineers handling multinational projects, using a globally recognized, certified system simplifies approval processes and enhances project credibility. Trusted Technology for Smarter Fire Safety Engineers choose GST Addressable Fire Alarm Panels not just for their brand reputation but for their intelligent, integrated and reliable design. From addressable detection and loop networking to event logging, system integration and compliance, every feature is engineered to deliver maximum safety, performance and scalability. In today’s industrial world, where fire safety is linked directly to business continuity and compliance, GST panels empower engineers to design efficient, cost-effective and future-ready fire detection systems. Read Also: 5 Things to Check Before Buying an Industrial Gigabit Switch Read Also: Top 5 Reasons Engineers Choose GST Addressable Fire Alarm Panels

Top 5 Reasons Engineers Choose GST Addressable Fire Alarm Panels

Fire safety has evolved beyond traditional alarm systems. Today’s modern buildings from manufacturing plants and warehouses to IT parks and healthcare facilities require intelligent, reliable and standards-compliant fire alarm systems that ensure early detection and seamless control. Among the many brands available in the market, GST Addressable Fire Alarm Panels have become a preferred choice for engineers, consultants and system integrators worldwide. Known for their precision engineering, advanced networking and international compliance, GST systems deliver exceptional performance in mission-critical environments. In this article, we explore the top five reasons engineers choose GST Addressable Fire Alarm Panels over other brands, with a clear focus on performance, compliance, scalability, integration and lifecycle value. 1. Proven Reliability and Global Certifications When it comes to fire safety, reliability isn’t optional, it’s essential. Engineers often prioritize brands with a strong track record of dependability and GST delivers exactly that. a. Certified for International Standards GST Addressable Fire Alarm Panels are fully compliant with international safety standards, including: These certifications ensure that GST systems perform consistently under the most demanding conditions, a key reason why engineers trust GST for industrial and large commercial projects. b. Reliability in Harsh Environments Many GST fire alarm systems are designed and tested to operate in industrial and hazardous conditions, including high-temperature zones, dusty manufacturing environments and chemical plants. Engineers appreciate GST’s robust hardware design, which includes surge protection, communication redundancy and fault-tolerant wiring, ensuring the system stays operational even under challenging circumstances. 2. Intelligent Addressable Technology for Faster Response Unlike conventional fire alarm systems that provide zone-based alerts, GST Addressable Panels offer point-to-point detection and monitoring. This means each detector, manual call point, or module is assigned a unique address, allowing the system to precisely identify the location of a fire or fault. a. Faster Detection, Smarter Decision Making When a detector is triggered, the control panel immediately identifies the exact device and location such as “Smoke Detector No. 32 in Zone 5 – 2nd Floor Electrical Room.”This enables rapid response by security or maintenance teams, reducing potential damage and downtime. b. Two-Way Communication GST Addressable Systems use digital communication protocols that allow real-time feedback between the panel and field devices. Engineers benefit from continuous health monitoring. The system can automatically report detector contamination, line faults, or maintenance reminders, improving system uptime and reducing manual inspection time. c. Scalable System Architecture GST Addressable Panels such as the GST-IFP8, GST-200N, and GST-5000 are designed to handle a wide range of projects, from small offices to mega-industrial complexes. Their loop-based architecture supports up to 250 devices per loop (depending on the model), allowing easy expansion without extensive rewiring. This flexibility makes GST panels an ideal choice for engineers planning phased or scalable projects. 3. Seamless Integration with Building and Industrial Systems In modern smart facilities, integration is everything. Engineers need systems that not only detect fires but also communicate efficiently with other subsystems like access control, HVAC and BMS (Building Management Systems). a. Built-in Communication Interfaces GST Addressable Fire Panels come equipped with RS-485, Modbus and TCP/IP communication options, allowing direct integration with other intelligent systems. For instance, a fire event can automatically: This seamless interaction enhances overall safety and operational control. b. Centralized Monitoring with GST Graphic Software The GST Graphical Monitoring and Control Software (GST G-MAP) allows engineers to visualize real-time events on digital floor maps. It helps operators quickly locate active alarms, faults, and disablements and supports remote control functions such as silence, reset or test operations. This centralized visualization is especially valuable in large industrial campuses, airports or multi-building complexes. 4. Cost Efficiency and Long-Term Value Engineers and facility managers must often balance safety performance with budget constraints. GST manages to deliver both, high-end features at a competitive cost. a. Optimized Lifecycle Cost While the initial investment in an addressable system may be higher than a conventional one, GST panels offer lower maintenance costs and reduced downtime over time. Their advanced diagnostics, self-testing features and modular design minimize the need for frequent manual checks or costly replacements. b. Backward Compatibility GST ensures that new panels remain backward compatible with existing field devices and loop components. This makes it easy for engineers to upgrade old installations without replacing the entire system, a significant advantage in retrofitting projects or facility expansions. c. Wide Availability and Technical Support GST’s extensive global network of distributors, service partners and certified engineers ensures easy access to spare parts, software updates, and technical assistance. For engineers, this means faster project completion, simplified commissioning and reliable post-installation support. 5. Engineer-Friendly Design and Commissioning Tools One of the biggest reasons engineers favor GST systems is their user-centric design. From installation to programming and maintenance, every step is made simple, efficient and intuitive. a. Simplified Programming Interface GST panels feature a Windows-based configuration tool (GST Programming Software) that allows engineers to program and upload configurations quickly. Device addresses, zones and logic functions can be defined on-screen, reducing manual errors and commissioning time. b. Clear LCD Display and Intuitive Navigation The panel’s graphical LCD interface displays live system information, including fire, fault or disable status. Engineers can navigate menus easily for diagnostics, testing or event log review. c. Modular and Expandable Hardware GST Addressable Panels come in modular configurations, allowing engineers to add additional loops, output cards or interfaces as the project grows. This plug-and-play expandability supports long-term flexibility, ensuring the system evolves alongside facility needs. d. Simplified Maintenance The built-in event log, maintenance report generation and loop testing tools help engineers perform regular audits without disrupting operations. With intelligent fault diagnostics, engineers can quickly pinpoint and resolve issues, improving reliability and reducing service costs. GST (Gulf Security Technology): Trusted Brand with a Global Presence GST, a brand under Carrier Global Corporation, has over two decades of experience in fire detection and alarm solutions. Their systems are deployed across thousands of critical installations including: Engineers trust GST not only for its products but also for its proven service ecosystem, training programs and compliance with regional fire codes (like

5 Things to Check Before Buying an Industrial Gigabit Switch

In today’s connected industrial environments, data speed, uptime and reliability are critical. Whether it’s for automation systems, smart warehouses, surveillance networks or industrial IoT setups, the industrial Gigabit switch acts as the communication backbone that keeps everything running smoothly. However, choosing the right switch isn’t as simple as picking one with a familiar brand name or the most ports. The right choice depends on several technical and environmental factors that directly impact performance, scalability and durability. In this guide, we’ll break down the five most important things you should check before buying an industrial Gigabit switch, so you can make an informed and future-ready investment. 1. Environmental Ruggedness and Durability Unlike commercial network switches, industrial Gigabit switches are designed for harsh environments. They’re often installed in locations with extreme temperatures, high humidity, dust, vibration and even electromagnetic interference (EMI). When evaluating an industrial switch, the first thing to check is whether it’s built to withstand such conditions. Key factors to consider: Pro Tip: Always verify if the switch complies with industry certifications like CE, FCC, UL and RoHS. These confirm quality, safety and environmental compliance. 2. Network Performance and Bandwidth Requirements Performance is the heart of any industrial switch. Gigabit switches promise high-speed data transfer, but their real-world performance depends on internal hardware capabilities and network design. Here’s what to evaluate: Pro Tip: For high-performance applications like HD video monitoring or industrial automation, prefer Layer 3 managed switches that offer routing and advanced traffic control. 3. Managed vs. Unmanaged: Choose What Fits Your Network Before buying an industrial Gigabit switch, you must decide whether you need a managed or unmanaged model. Both serve different purposes, and the right choice depends on your network size, control requirements and budget. Unmanaged Switches Managed Switches Pro Tip: If your network involves automation systems, IoT devices or multiple subnetworks, a managed industrial switch is a must-have. It ensures data segmentation, prevents broadcast storms and allows remote troubleshooting. 4. Power Options: PoE and Redundant Power Inputs In industrial setups, reliability is directly tied to consistent power delivery. Many modern industrial Gigabit switches come equipped with Power over Ethernet (PoE) and dual power input options to ensure uptime and efficiency. Why Power Matters: Pro Tip: Choose a switch that supports wide DC voltage input (e.g., 12–57VDC) for flexibility across different industrial power systems. 5. Expandability, Mounting and Network Integration Your industrial network should be built with future scalability in mind. As operations grow, so will your connectivity needs. Therefore, your Gigabit switch should be flexible and expandable enough to handle future demands. Key things to check: Pro Tip: Always check if the manufacturer provides long-term firmware support and integration with network management systems (NMS) for easier lifecycle management. Certifications and Vendor Support Before finalizing your purchase, verify that the switch meets relevant industrial standards and certifications. Look for: Also, choose a vendor known for technical support, warranty coverage and firmware updates. In industrial environments, downtime can be costly, so vendor reliability matters as much as product specs. Selecting the right industrial Gigabit switch goes beyond speed or brand. It’s about reliability, scalability and long-term performance in challenging environments. Before you buy, always check these five essentials: Investing in the right industrial switch ensures stable communication, seamless automation and future-ready network infrastructure. By focusing on quality and certifications, you not only improve uptime but also enhance safety and efficiency across your operations. Read Also: Benefits of Using GST Addressable Fire Alarm Panels for Industrial Purpose Read Also: Why Contractors Prefer GST Addressable Fire Alarm Panels

Why Contractors Prefer GST Addressable Fire Alarm Panels

When it comes to modern fire detection systems, efficiency, reliability and ease of commissioning are top priorities for contractors and system integrators. Among the numerous fire alarm brands available in the market, GST Addressable Fire Alarm Panels have earned a solid reputation for simplifying installation, configuration and maintenance processes. Whether you are setting up a small commercial facility or a complex industrial network, GST panels offer unmatched flexibility and intuitive configuration options. In this article, we’ll explore why contractors prefer GST Addressable Panels for their projects, focusing on easy commissioning, loop configuration, scalability and support tools that make every installation more efficient. 1. Understanding GST Addressable Fire Alarm Panels Before diving into why contractors favor GST panels, let’s briefly understand what they are. GST Addressable Fire Alarm Panels are intelligent control systems designed to detect and respond to fire incidents through addressable devices such as detectors, call points and modules connected via communication loops. Each device has a unique address, allowing the system to pinpoint the exact location of an alarm or fault. Unlike conventional panels, which divide zones manually, GST addressable systems automate detection and communication. This makes them highly efficient for buildings with complex layouts such as airports, hospitals, manufacturing plants and high-rise offices. 2. Simplified Commissioning Saves Time and Costs One of the main reasons contractors prefer GST addressable panels is the ease of commissioning. Commissioning a fire alarm system can often be a time-consuming and complex process, especially when dealing with hundreds or thousands of devices. However, GST simplifies this stage through intelligent design and user-friendly tools. Features That Simplify Commissioning: Overall, these features drastically reduce the time needed for commissioning. For a large-scale project, contractors can cut down configuration time by up to 40%, directly translating to lower labor costs and faster project delivery. 3. Easy Loop Configuration and Expansion Another reason GST addressable panels stand out is their loop flexibility and modular configuration. Most fire alarm systems rely on complex wiring structures, but GST’s loop architecture supports simple two-core wiring, which carries both power and communication. This streamlined wiring not only reduces installation errors but also simplifies future expansions. Advantages of GST Loop Configuration: Loop Expansion Made Simple Contractors often appreciate GST panels for their scalability. When a facility expands, new devices can be easily added to the existing loop without major rewiring. The panel’s auto-learning mode detects new devices and updates the loop configuration automatically. This flexibility makes GST panels ideal for evolving projects whether adding a new floor to a building or expanding a warehouse. 4. Intuitive User Interface and Programming Software Contractors don’t just look for reliable hardware, they want systems that are easy to interact with. GST panels come with an intuitive interface and powerful software tools that simplify programming and diagnostics. GST Programming Tools: The combination of hardware and software optimization ensures that contractors can configure loops, set alarm logic and perform tests with minimal technical hurdles. 5. Reduced Wiring Complexity and Maintenance Traditional fire alarm systems often require separate circuits for detection and alarm signaling. GST’s addressable technology integrates both power and communication in a single loop, dramatically reducing wiring complexity. Benefits for Contractors: In the long term, these advantages not only save costs but also reduce downtime during maintenance and upgrades, key factors contractors consider when choosing a fire detection brand. 6. Reliable System Diagnostics and Troubleshooting During installation or routine maintenance, diagnostic efficiency plays a major role. GST addressable panels are designed with built-in diagnostic functions that make troubleshooting straightforward. Diagnostic Highlights: This advanced diagnostic ecosystem makes GST panels contractor-friendly, allowing for quick fault isolation, accurate reporting and minimal downtime. 7. Scalable Design for All Project Sizes GST panels are available in a wide range of models, from small single-loop panels to large multi-loop networked systems such as GST-IFP8, GST-200, and GST-100. This scalability enables contractors to use the same platform across multiple project types, commercial offices, shopping malls, or industrial plants, without having to learn a new interface each time. Scalability Advantages: This unified approach enhances productivity and reduces training costs for installation teams. 8. Global Standards and Certification Compliance Contractors working on international or government projects often need products that meet global safety and quality certifications. GST panels are certified under multiple international standards such as: These certifications assure that GST systems meet the highest reliability and safety benchmarks, giving contractors confidence in both compliance and performance. 9. Comprehensive Technical Support and Training GST has built a strong global presence with a network of authorized distributors, service partners and training centers. Contractors can easily access technical resources, online manuals and troubleshooting guides. Support Features: This ecosystem ensures that contractors are never left unsupported during any project phase, from design to handover. 10. Why Contractors Continue to Choose GST To summarize, contractors prefer GST Addressable Fire Alarm Panels because they deliver efficiency, reliability and flexibility in every phase of the project. From simplified commissioning to smart loop configuration, GST panels are designed to make the contractor’s job easier and faster, without compromising on safety or compliance. Key Takeaways: In today’s fast-paced construction and industrial environment, time, precision and compliance are crucial. GST addressable panels tick all these boxes, making them the go-to choice for contractors, engineers, and facility managers worldwide. Note: As buildings become smarter and regulations more stringent, the demand for intelligent, easily manageable fire detection systems continues to rise. Contractors value GST panels not only for their technical excellence but also for their practical design that reduces human error, saves time and ensures seamless system performance. Whether it’s a new project or an upgrade, choosing GST Addressable Fire Alarm Panels is a decision that simplifies installation, enhances safety and delivers long-term reliability, exactly what every contractor looks for. Read Also: Deploying GST Addressable Systems in Hazardous Zones (ATEX & Industrial Compliance) Read Also: Benefits of Using GST Addressable Fire Alarm Panels for Industrial Purpose

Benefits of Using GST Addressable Fire Alarm Panels for Industrial Purpose

Industrial environments such as manufacturing plants, warehouses, refineries, logistics hubs, chemical units, data centres and large infrastructure facilities demand highly reliable, intelligent and responsive fire alarm systems. Traditional conventional panels are no longer sufficient for handling complex layouts, high-risk zones and performance compliance needs. This is where GST addressable fire alarm control panels offer a major advantage. GST has established itself as one of the most trusted brands globally in fire detection and alarm systems. Its range of addressable fire alarm panels, including the GST-IFP4E, GST-IFP8, GST100 Series and GST200N Series, offers industrial-grade reliability, system scaling flexibility, integration capabilities and compliance with global standards. This detailed article explores the industrial benefits of using GST addressable fire alarm panels with a model-wise breakdown, ensuring clarity for engineers, consultants, system integrators, facility managers and decision-makers. Why Addressable Fire Alarm Systems Are Ideal for Industrial Use Before diving into specific models, it’s important to understand why addressable technology itself is preferred in industrial settings. 1. Pinpoint Fire Location Each device (detector, MCP, module, hooter) has a unique address. When fire, fault, or smoke is detected, the exact location appears on the panel. 2. Reduced False Alarms Industrial environments often generate dust, fumes or vapors. Addressable panels allow sensitivity adjustment and selective isolation to reduce false triggers. 3. Lower Maintenance & Troubleshooting Time Technicians can quickly identify faulty components using the device address, reducing system downtime. 4. Integration with BMS & Suppression Systems Industry-grade automation demands centralized safety monitoring. GST panels interface easily with sprinklers, smoke control, PA systems and PLC-based processes. 5. Multi-Loop & Multi-Zone Flexibility Ideal for industrial layouts with large floor areas, multi-block structures, warehouses, assembly zones and hazardous sections. 6. Better Compliance & Documentation Complies with NFPA, EN54, IS standards, insurance norms and fire safety audit requirements. GST Model-wise Benefits for Industrial Applications Now let’s analyze the benefits of each specific GST addressable fire alarm panel used across industrial environments. 1. GST-IFP4E: Advanced Touchscreen Panel for Large-Scale Industrial Systems Best suited for: Key Benefits: 2. GST-IFP8: Trusted Addressable Control Panel for Diverse Industrial Use Ideal for: Industrial Benefits: 3. GST100 Series: Compact Intelligent Panel for Small to Mid-Size Industries Best application areas: Benefits: 4. GST200N Series: Intelligent & Flexible Panel for Medium to Large Industrial Facilities Most effective in: Industrial Strength Features: Industrial Advantages of GST Addressable Panels Beyond individual models, GST addressable systems provide broader benefits for industrial safety and operations. 1. Enhanced Fire Detection Accuracy Early-stage fire detection prevents production loss and asset damage. 2. Compliance with Safety Regulations Meets FM, LPCB, UL, EN54, IS, NBC, TAC and factory safety norms. 3. Zero Production Downtime Addressing faults before escalation ensures uninterrupted operations. 4. Minimal Cabling & Lower Installation Cost Loops reduce wiring complexity compared to traditional zones. 5. Centralized Command & Control Multiple buildings can be monitored from one room. 6. Remote Monitoring Capabilities Ideal for large campuses and multi-site industries. 7. Reduced False Alarms Sensitivity adjustments and intelligent algorithms help minimize nuisance alarms. 8. Easy Maintenance & AMC Support Real-time panel diagnostics and address mapping simplify servicing. 9. Scalable for Future Growth When a plant expands, loops and modules can be added without replacing the core system. 10. Integration with Industrial Safety Ecosystems GST panels can connect with: Real-World Industrial Use Cases Here are some examples of how GST addressable panels support industrial safety: Manufacturing Plant A GST-IFP4E panel with multi-loop integration and repeater panels manages over 3,000 devices across shop floors, power rooms, storehouses and administrative blocks. Auto Component Industry A GST200N controls fire alarms, suppression modules and hooters in different bays while interfacing with emergency lighting systems. Pharma Units GST100 Series monitors cleanrooms, packing zones and dispatch areas with high-sensitivity detectors to prevent chemical ignition risks. Refineries & Oil Depots GST-IFP8 provides addressable control for explosion-proof detectors and zone modules, ensuring compliance with hazardous area classification. Integration Capabilities for Industry 4.0 GST panels offer strong digital transformation compatibility: This level of automation is critical for intelligent manufacturing and smart industrial hubs. AMC & Lifecycle Benefits When paired with an Annual Maintenance Contract (AMC), GST panels deliver: This extends system lifespan and ensures insurance/audit readiness. Choosing the Right GST Panel for Industrial Needs Here’s a quick reference based on facility size and complexity: Industrial Requirement Recommended GST Model Small workshops / storage GST100 Series Medium industrial units GST200N Large plants / multi-floor sites GST-IFP8 Large campuses and refineries GST-IFP4E GST addressable fire alarm panels are engineered to meet the demanding requirements of industrial environments. Each model from GST100 Series to GST-IFP4E offers performance benefits tailored to facility size, risk level and compliance needs. Why industries prefer GST addressable systems: Whether you’re upgrading safety in a warehouse, automating alerts in a chemical plant, or monitoring multiple production units, GST addressable panels provide a scalable, intelligent and future-proof solution. Read Also: Choosing Between GST-IFP8, GST-200 & GST-5000: Model Comparison for Large Projects Read Also: Deploying GST Addressable Systems in Hazardous Zones (ATEX & Industrial Compliance)

Deploying GST Addressable Systems in Hazardous Zones (ATEX & Industrial Compliance)

Industrial environments such as refineries, chemical plants, oil and gas terminals and pharmaceutical manufacturing facilities often contain flammable gases, combustible particulates or volatile vapors. These areas are classified as hazardous zones and are governed by strict safety directives like ATEX (Europe), IECEx (international) and NEC (North America). Traditional fire alarm systems are not adequate in such environments because ignition risks are high, explosion hazards are present and detection time is critical. GST Addressable Fire Alarm Systems, when properly selected, certified and deployed, can help organizations achieve reliable protection in hazardous zones while ensuring compliance with ATEX and related industrial safety regulations. This comprehensive guide explains how GST addressable systems can be implemented in hazardous zones, what standards must be met and the best practices that ensure safety and regulatory compliance. 1. What Are Hazardous Zones and ATEX Classifications? A hazardous zone is any location where explosive atmospheres caused by gases, vapors, mists or dust may exist. These areas are commonly found in: To manage risks, regulatory frameworks classify zones based on the likelihood of explosive atmospheres. ATEX Zone Classifications (for EU & IECEx regions): Dust-Based Zones: To operate in such zones, fire detection and alarm systems must use hardware that is explosion-proof, intrinsically safe and fully compliant with ATEX directives. 2. Why Choose GST Addressable Systems for Hazardous Zones? GST addressable fire alarm systems are engineered to provide precise, intelligent and scalable detection across complex industrial settings. When deployed with explosion-proof and ATEX-certified devices, they offer several advantages: 3. ATEX & Industrial Compliance Requirements Before deploying GST systems in hazardous zones, organizations must meet the following compliance criteria: ✔ Equipment Certification Fire detectors, call points, sounders and interfaces must be certified under: ✔ Intrinsic Safety (IS) Design In areas with high explosion risk, circuits must use: ✔ Cable and Wiring Compliance Cables must be resistant to: ✔ Installation Standards Compliance with: ✔ Maintenance Requirements Regular ATEX-certified inspections and preventive maintenance routines are mandatory. 4. Components of a GST Addressable System for Hazardous Zones A compliant setup typically includes: 5. Step-by-Step Deployment Process Step 1: Site Assessment & Hazard Mapping Map hazardous zones (0/1/2/20/21/22) and identify ignition risks, temperature classes and protection concepts. Step 2: Device Selection Use only: Step 3: Loop Design & Wiring Step 4: Panel Programming Assign unique addresses, configure zones and activate alarm verification logic. Step 5: Testing & Commissioning Perform: Step 6: Documentation & Compliance Inspection Maintain logs of equipment certification, loop drawings, device address sheets and inspection records. 6. Industry-Specific Use Cases 7. Best Practices for Compliance & Safety To ensure long-term reliability in hazardous environments: 1. Use Only Certified Equipment Always check ATEX, FM, IECEx, PESO or UL marks. 2. Implement Redundant Loops Maintain operation even if one segment is compromised. 3. Protect Cables and Junctions Use metal conduit, armored cable, or tray systems. 4. Perform Frequent Inspections Inspect enclosures, barriers and field wiring at planned intervals. 5. Train Maintenance Teams Educate technicians on handling IS devices and zoning protocols. 6. Align With Fire Safety Authorities Comply with local fire departments, insurance agencies and government safety boards. 8. Challenges and How to Overcome Them Challenge Solution Harsh environmental exposure Use IP66/IP67 rated devices Voltage drops in long loops Implement addressable isolators and boosters False alarms due to dust or vapors Use heat/flame detectors with adaptive logic Certification limitations Coordinate with approved integrators Integration with suppression systems Use relay modules and fault monitoring 9. Maintenance & Lifecycle Compliance Even after installation, hazardous zone systems need constant monitoring: GST addressable control panels provide real-time fault diagnostics, logs and loop management features that simplify long-term upkeep. 10. Benefits of Using GST Addressable Systems in Hazardous Zones Here’s a quick overview of the advantages: Deploying GST Addressable Systems in hazardous zones requires a structured approach, certified hardware and strict conformity with ATEX and industrial safety standards. When designed and installed correctly, these systems provide unmatched protection, fast detection and seamless integration with existing safety infrastructure. From oil refineries to chemical processing units and dust-prone facilities, GST fire alarm solutions play a pivotal role in mitigating explosion risks while maintaining compliance and operational continuity. Whether you are a system integrator, facility manager, fire safety consultant or safety compliance officer, implementing ATEX-certified GST Addressable systems is an investment in safety, reliability and long-term cost control. Read Also: Implementing GST Addressable Fire Systems in Industrial Plants: Safety & Compliance Guide Read Also: Choosing Between GST-IFP8, GST-200 & GST-5000: Model Comparison for Large Projects

Choosing Between GST-IFP8, GST-200 & GST-5000: Model Comparison for Large Projects

Selecting the right fire alarm control panel (FACP) for a large project isn’t just about picking the biggest model, it’s about matching system capacity, expansion needs, compliance, integration and life-safety workflows to your facility. This article compares three commonly used GST control panels, GST-IFP8, GST-200 (GST200N family) and GST-5000 and gives guidance for engineers, system integrators, facility managers and consultants who must choose the most appropriate platform for large commercial, industrial, data-centre or campus projects. Quick Takeaway Why this Comparison Matters Large projects impose several requirements that small installs don’t: lots of detectors and interfaces, multiple evacuation zones, distributed control rooms, redundancy expectations, integration with voice alarm or BMS and maintainability during operation. Picking the wrong panel creates hidden costs: extra repeaters and network complexity, difficult programming, expensive future upgrades or non-compliance with project specifications. This comparison focuses on capacity, expandability, compliance & integration, field usability and suitability for project types. Specification at a Glance (These figures are drawn from GST product literature and installation manuals; always confirm final technical selection against the latest datasheets for the exact SKU you plan to buy.) Detailed Feature Comparison 1. Capacity & Scaling 2. Networkability & Distributed Systems 3. Integration (Voice, BMS, Gas-release, Fireman’s panels) 4. Compliance & Standards All three models are designed to meet international fire safety standards (EN-54 parts, LPCB listing in some variants), but compliance depends on the specific SKU and regional approvals. Confirm the exact model and firmware meet local codes and the project’s specification. 5. Usability, Diagnostics & Maintenance Selection Process for Large Projects Typical Project Examples and Suggested Picks Final Considerations & Procurement Tips For large projects, you should prioritize system architecture and lifecycle over the sticker price. The GST-200 family suits compact, budget-sensitive installs. The GST-IFP8 is a robust mid-to-large building solution with high device capacity in one chassis. The GST-5000 is the enterprise option: modular, networkable and built for campus-scale deployments with advanced integration. Use a requirements-driven checklist, verify certifications and site-specific constraints and involve both the developer/manufacturer and the end-user’s O&M team during procurement to ensure the chosen platform meets operational and safety goals.