Modern buildings demand a fire alarm system that responds fast, communicates clearly and adapts to changes over time. Addressable fire alarm systems meet these expectations because they offer flexibility, intelligence and precise pinpointing of alarm locations.

Among all addressable system brands, GST (Gulf Security Technology) has become a widely adopted choice across malls, hospitals, corporate towers, hotels, manufacturing units, airports and government buildings, mainly because its modular design allows integrators to build systems that are both scalable and future-ready.

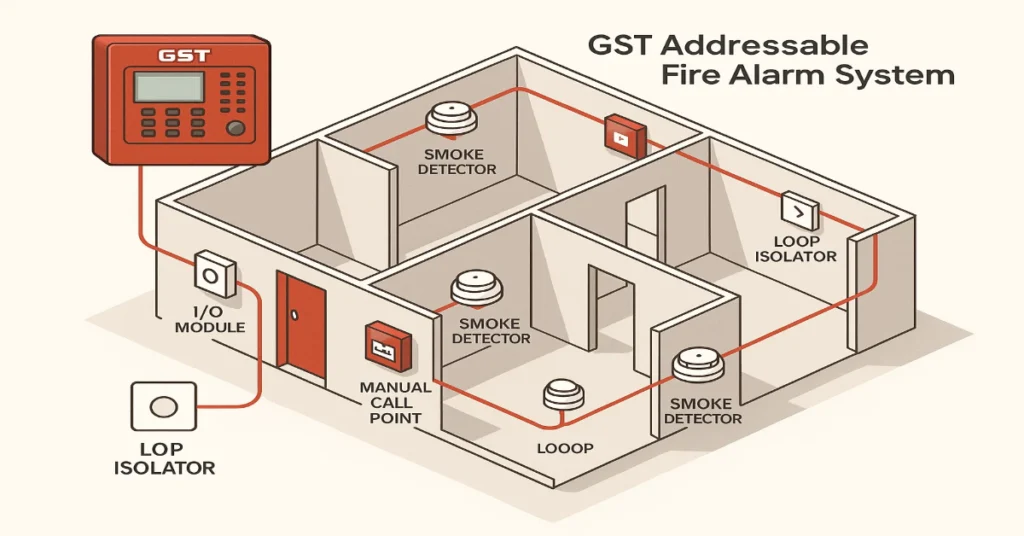

While panels, detectors and manual call points often receive the attention, the real backbone of an addressable system lies in its modules, especially I/O modules and loop isolators. These components silently ensure that the system works smoothly, even in harsh electrical conditions or during expansion, retrofitting or integration with third-party equipment.

This article explores why I/O modules and loop isolators are essential for any GST addressable system, how they function, how they are used and how they future-proof fire safety infrastructure.

Why Modules Matter in an Addressable Fire Alarm System

To understand the importance of modules, you first need to understand the architecture of an addressable fire alarm loop.

A loop connects all devices, detectors, call points, sounders and modules back to the fire alarm control panel. Every GST addressable device has a unique address, allowing the panel to identify where an incident occurs.

But what happens when:

- You want to integrate fire alarms with HVAC shutdown?

- A fire pump needs to start automatically?

- Access control doors must release during an emergency?

- A section of the loop gets shorted or damaged?

- You need to create fire-safe zoning in a large facility?

This is exactly where modules come into play. They enable the system to perform additional tasks, communicate with external equipment and isolate faults so the loop continues functioning.

Understanding the Two Most Critical Modules – I/O Modules & Loop Isolators

Below is a deep and practical explanation of their roles in any GST addressable system.

I/O Modules: The Communication Bridge for Fire System Integration

I/O modules (Input/Output modules) are among the most frequently used components in any addressable system. They work as translators between the fire alarm panel and external third-party systems.

What an I/O Module Does

An I/O module allows the fire panel to:

- Receive signals from external systems

- Send commands to external systems

- Perform automatic actions based on fire conditions

In other words, every time a fire alarm needs to trigger something or monitor something, you need an I/O module.

GST’s addressable I/O modules are used widely because they:

- Offer stable communication

- Support multiple output modes

- Allow flexible zoning and cause-and-effect programming

- Integrate seamlessly with HVAC, lifts, pumps, and more

Where I/O Modules Are Essential

Below are typical real-world scenarios where an I/O module becomes mandatory.

Fire Pump Start/Stop Commands

The fire alarm system must start the pump automatically when a sprinkler flow switch or deluge valve is triggered. The I/O module receives the feedback and issues the command.

AHU & HVAC Shutdown

To prevent smoke circulation, the panel must shut down:

- Air Handling Units

- Ventilation fans

- Smoke extraction systems

An I/O module ensures immediate action during a fire event.

Lift Grounding and Door Release

Most buildings integrate:

- Lift grounding

- Lift recall

- Elevator fire mode

- Magnetic lock release

I/O modules handle all these commands through cause-and-effect programming.

Access Control, Turnstiles & Barrier Systems

Safety protocols require instant unlocking of gates and access points. I/O modules ensure all secured doors open when a fire occurs.

Integration with Gas Suppression Systems

For suppression rooms such as:

- Server rooms

- Electrical control rooms

- Data centers

- UPS rooms

I/O modules handle:

- Pre-discharge alarms

- Agent release signals

- Abort switches

- Cylinder pressure monitoring

Sprinkler and Valve Monitoring

When sprinkler zones activate, the I/O module sends feedback to the fire control panel for immediate display.

Monitoring Third-Party Panels

I/O modules integrate:

- BMS

- PA systems

- Security alarms

- VESDA systems

- Emergency lighting panels

This makes the fire alarm panel the central command unit of the building.

Advantages of Using Quality I/O Modules in GST Addressable Systems

1. Smooth Integration Without Errors

GST modules ensure reliable communication even in high-noise electrical environments.

2. Modular Upgradability

They support expansion without changing the entire loop design.

3. Cost-Effective Design

Only the required number of modules are added, avoiding over-engineering.

4. Precise Addressability

Every module provides pinpoint location and status, improving emergency response.

5. Stable Cause-and-Effect Logic

GST’s modules align perfectly with the panel’s programmable logic, ensuring predictable, safe automation.

Loop Isolators: The Insurance Policy for Loop Health

Loop isolators are another must-have module for any GST addressable system. They protect the fire alarm loop from complete failure by isolating faulty sections.

Why Loop Isolators Are Mandatory

Addressable loops operate on continuous communication. If a short circuit occurs:

- The entire loop can fail

- All devices downstream become non-functional

- Fire alarms may not trigger

- System reliability collapses

Loop isolators prevent this catastrophic chain reaction.

How Loop Isolators Work

A loop isolator is placed at regular intervals on the loop. When it detects a short or fault:

- It cuts off the affected section

- Keeps the remaining loop operational

- Protects the panel from overcurrent

- Ensures uninterrupted functionality in case of wiring damage

In GST systems, loop isolators react extremely fast, ensuring downtime is nearly zero.

Where Loop Isolators Should Be Installed

1. Between Every 20–25 Devices

Industry standards and best practices recommend spacing isolators based on device load and loop length.

2. At Each Floor Entry/Exit

This ensures one floor fault does not impact others.

3. Before and After High-Risk Areas

Like:

- Parking basements

- Transformer rooms

- Mechanical floors

- Wet sprinkler areas

4. At the End of Long Cable Runs

To limit the fault zone and maintain loop integrity.

Advantages of Loop Isolators in GST Addressable Systems

1. Prevents Full Loop Failure

Only the faulty section is isolated.

2. Faster Troubleshooting

The panel displays the isolated address, helping technicians locate the problem quickly.

3. Improves System Reliability

Even during faults, life-safety devices continue operating.

4. Enhanced Safety in Large Buildings

They are especially crucial in malls, airports, hospitals and IT campuses with long loops.

5. Supports Stable Loop Voltage

Isolators maintain uniform power and communication levels across the loop.

Why GST’s Modular Approach Makes System Design Easier

While many brands offer modules, GST’s addressable architecture is known for:

- Compatibility across device generations

- Interference-resistant communication

- Reliable loop power management

- Easy programming using standard tools

- High stability in noisy electrical environments

This allows consultants and integrators to design systems that are:

- Cost-efficient

- Scalable

- Easy to maintain

- Future-ready

How to Choose the Right Modules for Your Project

Selecting the correct number and type of modules ensures optimal performance. Below is a simple selection framework.

Choosing I/O Modules: Key Parameters

Determine Integration Needs

List all equipment requiring command or monitoring signals:

- Pumps

- AHUs

- Fire doors

- Control panels

- Security systems

Check Input/Output Requirements

Choose modules with:

- Single input

- Single output

- Multi-input

- Multi-output

depending on project needs.

Consider Cable Routing

Modules should be placed near the equipment they control to reduce cable cost.

Metering & Monitoring

Ensure modules support:

- Supervised inputs

- Feedback monitoring

- Fault reporting

Choosing Loop Isolators: Key Parameters

Loop Length and Load

Longer loops need more isolators.

Building Layout

Place isolators at:

- Staircases

- Floor transitions

- Zonal junctions

Risk Assessment

Install additional isolators near equipment rooms or areas prone to mechanical damage.

Manufacturer Compatibility

Always use isolators recommended for your loop, GST isolators are optimized for GST panels.

Best Practices for Installing Modules in a GST Addressable System

Use Approved Enclosures

Protect modules from dust, moisture and tampering.

Maintain Cable Segregation

Avoid running fire cables alongside high-voltage lines.

Ensure Proper Addressing

Assign logical addresses for easy troubleshooting.

Test All Input/Output Logic

Before handing over, test:

- Door release

- Lift recall

- Pump activation

- Fan shutdown

Document Cause-and-Effect

Keep records of how modules interact with third-party systems.

Periodic Maintenance

During maintenance:

- Check loop voltage

- Test isolator operation

- Verify input/output commands

This ensures the system remains dependable for years.

How Modules Enhance Safety, Efficiency & System Longevity

Modules are not just accessories, they are core contributors to:

Safety

- Faster automated responses

- Fault-tolerant operation

- Reliable integration

Efficiency

- Reduced manual intervention

- Precise zoning

- Intelligent control

Long-Term Savings

- Lower maintenance costs

- Scalability without rewiring

- Reduced downtime

Future Trends in GST Addressable System Modules

GST’s infrastructure-ready ecosystem enables new innovations such as:

- Smarter addressable modules

- Cloud-enabled monitoring

- Predictive maintenance using analytics

- Reduced wiring complexity through enhanced loops

- Higher integration capabilities with BMS and IoT

As buildings evolve, module-based fire safety will remain central to creating intelligent, resilient facilities.

Note: I/O modules and loop isolators are essential for building a robust, reliable and intelligent GST addressable system. They ensure seamless communication with external systems, maintain loop health and improve safety performance across all building types. Whether you are designing a fire alarm system for a mall, hospital, data centre, airport, hotel, corporate campus or industrial plant, these modules are non-negotiable.

A well-designed GST addressable system, equipped with the right modules, ensures long-term reliability, compliance and peace of mind.

Read Also: Best Fire Alarm Panels for IT Parks & Tech Campuses

Read Also: Why Malls & Shopping Complexes Prefer GST Addressable Panels