Industrial sites are among the most complex environments when it comes to fire safety. With heavy machinery, large-scale electrical systems, combustible materials and human activity all under one roof, the consequences of a fire incident can be injurious. That’s why fire alarm network design plays a vital role in protecting both people and assets.

However, many industrial facilities, old and new, suffer from design errors that compromise system reliability, delay response times and violate key safety codes such as NBC (National Building Code) and NFPA (National Fire Protection Association) standards.

This article explores the most common fire alarm network design mistakes found in industrial settings, their real-world implications and practical ways to fix them.

Whether you’re a project consultant, system integrator or facility manager, these insights will help ensure your next installation is both compliant and fail-safe.

1. Ignoring Site-Specific Risk Assessment

The Mistake

One of the most frequent design flaws is using a one-size-fits-all approach. Many projects copy layouts from commercial or residential systems without considering unique industrial risks like flammable gases, high dust levels or vibration-prone equipment.

Why It’s a Problem

Each industrial plant, be it a refinery, power station, or manufacturing unit has different ignition sources and fire behavior patterns. Without a thorough Fire Risk Assessment (FRA), the placement and type of detectors may be completely ineffective.

For example:

- Heat detectors may be unsuitable in high-temperature zones.

- Smoke detectors may trigger false alarms in dusty or humid areas.

- Flame detectors may be missing where fuel storage or open flames exist.

The Fix

Conduct a detailed fire hazard analysis before designing the system. This includes:

- Mapping potential ignition sources.

- Identifying hazardous areas as per ATEX or IS/IEC 60079 standards.

- Selecting detectors rated for those environments (e.g., explosion-proof GST flame detectors for hazardous zones).

Pro Tip: Collaborate with both safety officers and process engineers to ensure the network design aligns with actual site conditions.

2. Incorrect Loop Loading and Power Calculations

The Mistake

Designers often overload loops by connecting too many detectors, sounders or modules beyond the control panel’s rated loop capacity. Some underestimate the voltage drop or fail to calculate standby battery backup, leading to system instability.

Why It’s a Problem

Overloaded loops cause:

- Device communication errors.

- Increased system downtime.

- Panel fault indications or device drop-offs.

- Failure during fire conditions when maximum load occurs.

The Fix

Follow the manufacturer’s loop calculator and documentation strictly. For example, GST Addressable Fire Alarm Systems provide precise guidelines on:

- Maximum number of devices per loop.

- Loop current ratings.

- Cable length limits.

Always include a 10-15% safety margin for future expansion. Use separate power supplies for high-load devices like strobes or hooters.

Pro Tip: Use loop isolators strategically to segment zones and maintain zero downtime in case of short circuits.

3. Poor Network Segmentation and Topology Planning

The Mistake

Designers sometimes daisy-chain all devices or panels without considering the physical layout, distance or redundancy requirements. This single-line dependency creates multiple single points of failure.

Why It’s a Problem

If one section of the loop or backbone fails, the entire segment goes offline, leading to delayed alarm transmission and compromised evacuation response.

The Fix

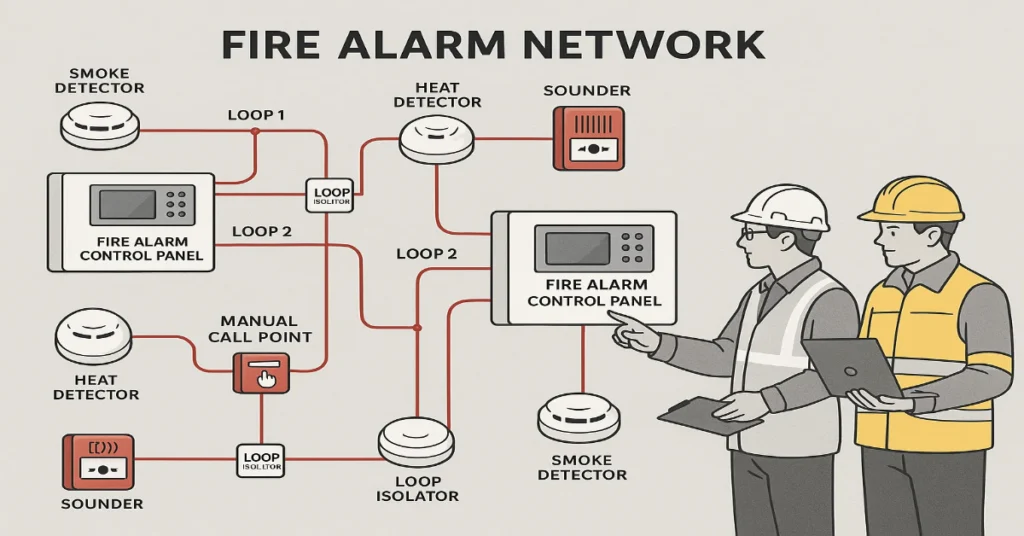

Adopt ring or redundant network topology using loop isolators and network cards. For large industrial campuses, use networked panels, each serving a separate building or production line, connected through fiber optic or RS-485 networks.

Ensure that:

- Each loop is isolated per floor or section.

- The control room receives live feedback from all panels.

- Network paths are physically separated to avoid common mode failure.

Pro Tip: Choose GST’s loop isolation modules to maintain communication integrity across distributed zones.

4. Inadequate Integration with Other Safety Systems

The Mistake

A common oversight is designing the fire alarm network in isolation from other building safety systems such as Public Address (PA), HVAC control, Access Control and Sprinkler systems.

Why It’s a Problem

Without integration, emergency actions like automatic fan shutdown, door release or sprinkler activation may not trigger automatically during an alarm. This can delay evacuation or worsen fire spread.

The Fix

Design for system interoperability using relay interfaces, communication modules or BACnet/Modbus gateways. GST fire panels, for example, support programmable logic interlinking, enabling seamless integration with:

- Fire suppression systems.

- Emergency lighting.

- Voice evacuation systems.

Pro Tip: During the design phase, create a cause-and-effect matrix mapping every alarm event to the required output action. This ensures complete coordination between subsystems.

5. Ignoring Cable Selection and Routing Standards

The Mistake

Many installations use incorrect cable types or improper routing methods such as running fire alarm cables alongside power lines, causing interference or signal loss.

Why It’s a Problem

Improper cables or routing can result in:

- Electromagnetic interference.

- False alarms or signal dropouts.

- Non-compliance with NFPA 70 (NEC) and IS/IEC 14520 standards.

The Fix

Use fire-rated, low-smoke zero halogen (LSZH) cables certified as per BS 7629-1 or IEC 60331. Ensure proper segregation from power and data cables, maintaining at least 300 mm of separation or using metal conduits.

Additionally:

- Label cables at both ends.

- Route them through fire-resistant trays or conduits.

- Test for continuity and insulation resistance before commissioning.

Pro Tip: Always keep updated cable layout drawings for future maintenance or troubleshooting.

6. Poor Detector Placement and Zoning

The Mistake

Another major issue is improper detector spacing and zoning, often due to misinterpretation of codes or lack of site survey.

Why It’s a Problem

- Detectors placed too close to walls or vents may not sense smoke effectively.

- In large workshops, coverage gaps can leave entire sections unprotected.

- Poor zoning confuses responders during emergencies.

The Fix

Follow NFPA 72 or IS 2189 guidelines for spacing:

- Smoke detectors: within 9.1 m radius (typical ceiling height ≤ 3.5 m)

- Heat detectors: within 5.3 m radius

- Minimum 0.5 m distance from walls or beams

Define logical zones corresponding to physical areas (e.g., “Boiler Room Zone A” or “Packing Section B”). This ensures responders can quickly locate and control the fire source.

Pro Tip: Use GST’s addressable detectors that provide device-level identification, enabling pinpoint accuracy during alarms.

7. Neglecting Redundancy and System Monitoring

The Mistake

Many industrial fire alarm networks lack redundancy in communication paths or backup monitoring systems.

Why It’s a Problem

In case of a single device, loop or panel failure, the entire monitoring system could go offline, leaving the facility unprotected for hours or days.

The Fix

Incorporate redundant loops, dual network paths and secondary control panels where possible. Use fault-tolerant architecture that allows continued operation even during partial failure.

Modern systems like GST Intelligent Fire Networks support dual-loop technology and self-diagnostic features, ensuring zero downtime in mission-critical zones.

Pro Tip: Include remote monitoring options through Ethernet or GSM modules for 24/7 supervision.

8. Overlooking Maintenance and Documentation

The Mistake

Even the most advanced fire alarm network fails if it’s not maintained properly. Many industrial sites lack updated documentation or skip regular inspection schedules.

Why It’s a Problem

- Undocumented changes make troubleshooting difficult.

- Dust, corrosion, or damaged cables may go unnoticed.

- Maintenance teams waste time identifying devices.

The Fix

Adopt a preventive maintenance plan in compliance with NFPA 72 Chapter 14 or IS 2189:2019. Maintain:

- Updated as-built drawings.

- Device ID lists and loop addresses.

- Test and service logs.

Pro Tip: Train in-house staff or tie up with an authorized GST service partner for annual audits and certification.

9. Failing to Plan for System Expansion

The Mistake

Designers often create fire alarm systems based on the current site layout, ignoring potential future expansion.

Why It’s a Problem

When the plant grows or adds new equipment, the existing fire network becomes overloaded or incompatible with new devices.

The Fix

Design with scalability in mind:

- Leave spare capacity on each loop and in the control panel.

- Choose addressable systems like GST 200/5000 series, which allow easy device additions.

- Use modular wiring schemes for quick reconfiguration.

Pro Tip: Plan for at least 20% spare capacity in every new design.

Designing a reliable and compliant fire alarm network for industrial sites demands more than just connecting devices, it requires a deep understanding of risk, system architecture and long-term maintainability.

By avoiding the common mistakes outlined above such as overloading loops, neglecting integration or skipping documentation, you can build a robust fire alarm system that ensures maximum safety, uptime and compliance.

A well-designed system doesn’t just meet codes; it saves lives and protects productivity.

For advanced, code-compliant solutions, consider GST Addressable Fire Alarm Systems, known for their loop isolation, intelligent detection and network scalability, perfect for complex industrial environments.

Read Also: Buy GST Smoke Detectors & Heat Detectors: Full Range for Commercial Buildings

Read Also: Buy Complete GST Addressable Fire Alarm System Package: Panel + Devices + Cables