Early and reliable fire detection is essential in commercial and industrial facilities, where fires can threaten human life, expensive equipment and continuous operations. For example, the U.S. Fire Administration reports that in 2022 commercial fire losses exceeded $411 million due to equipment and detection failures. Advanced Fire Detection Technologies helps facility managers and safety officers catch fires in the incipient stage, minimizing damage and downtime.

In large factories, warehouses, data centres or high-risk plants, every second of warning is valuable. Modern fire alarms protect assets and people by detecting heat, smoke, toxic gas, or combustion signatures faster and more accurately than older systems.

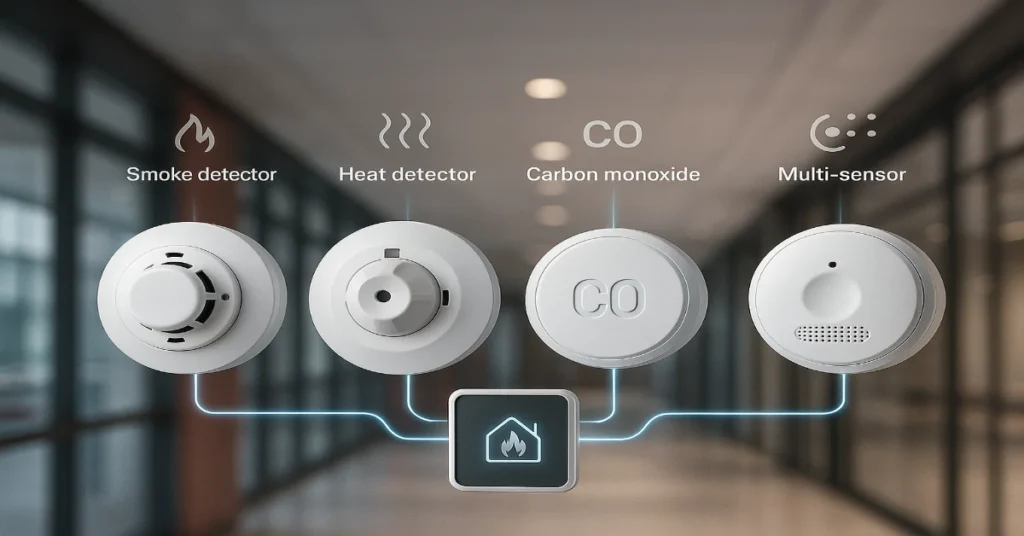

Commercial systems differ from home alarms: they must cover vast areas, harsh environments and avoid false alarms that disrupt operations. Traditional fire alarms used simple detectors (e.g. a single smoke detector or heat sensor per room) tied to a central panel. By contrast, advanced systems incorporate multiple sensor types, network connectivity and intelligent processing.

Traditional vs. Advanced Fire Detection

| Aspect | Traditional Fire Detection | Advanced Fire Detection |

|---|---|---|

| Detection Method | Single-criteria devices (e.g., smoke or heat only) | Multi-sensor devices (smoke, heat, gas combined) |

| Technology | Basic photoelectric or fixed-temperature detectors | AI/IoT-enabled detectors with data analysis |

| Wiring & Connectivity | Hardwired to control panel | Supports wireless and IP-based connections |

| Response Process | Alarm triggered, manual response by staff/firefighters | Automated alerts with remote/mobile notifications |

| Accuracy | Higher risk of false alarms (e.g., dust/steam) | Can differentiate between harmless conditions and real fire |

| Integration | Standalone system with limited connectivity | Integrates with Building Management Systems (BMS) |

| Best Suited For | Small/simple buildings | Large, complex, modern facilities |

| Overall Capability | Basic fire detection | Smart, predictive, and real-time fire safety |

Smoke Detection

Photoelectric Smoke Detectors: Photoelectric (optical) smoke detectors contain a light source and a photodetector in a sensing chamber. In normal conditions the light beam does not hit the sensor. When smoke enters, the particles scatter the light and some of this scattered light strikes the detector, triggering the alarm. These detectors are especially sensitive to large smoke particles from smoldering fires (like smoldering wood or cables).

Ionization Smoke Detectors: Ionization detectors use a tiny radioactive source (Americium-241) to ionize air molecules between two electrodes. This creates a constant electric current in clean air. When small combustion particles from a fast-flaming fire enter the chamber, they attach to the ions and interrupt the current flow. The drop in current triggers the alarm. Ionization sensors react quickly to fast flames and fine smoke (like from burning paper or liquids).

Aspirating Smoke Detection Systems: In large or sensitive facilities (data centres, clean rooms, telecom vaults), aspirating detectors offer very early smoke detection. These systems use fans to continuously draw air through a network of small pipes placed throughout the protected area. The sampled air is filtered and delivered to a central detection unit that contains highly sensitive optical sensors and sophisticated processing algorithms. Because aspirating detectors actively circulate air, they can catch even trace amounts of smoke long before a standard ceiling detector would trigger.

Large industrial spaces such as warehouses and factories often use aspirating smoke detection to cover wide areas. These systems actively sample air and can detect minute smoke particles for very early warning of fires. Their high sensitivity and sophisticated filtering make them effective even in dusty or high-airflow environments.

Heat Detection

Heat detectors respond to changes in temperature rather than smoke. This makes them useful in environments where smoke detectors could be triggered by nuisance sources. Heat detectors are also simpler and cheaper than many smoke detectors. There are two main types:

- Fixed-Temperature Detectors: These devices trigger an alarm when the ambient temperature exceeds a predetermined setpoint (often around 57-88 °C). They typically use a heat-sensitive element (like a bimetal strip or eutectic alloy) that activates an alarm circuit at the threshold. Fixed detectors are well-suited for areas prone to higher background heat or particulate-laden air, such as commercial kitchens, boiler rooms, or dusty manufacturing floors.

- Rate-of-Rise Detectors: These devices trigger an alarm if the temperature in the space climbs very rapidly (typically on the order of 8-11 °C per minute). A rate-of-rise detector usually has a heat-sensitive switch with a spring; if it heats quickly, the spring activates the alarm. These detectors are effective at catching fast-developing fires (e.g., chemical or fuel fires) that cause abrupt temperature spikes.

Many systems use combination detectors that incorporate both fixed and rate-of-rise functions. This provides the benefits of both: the detector will alarm either on a quick heat jump or if a critical temperature is reached. Combination units improve reliability in spaces with varying conditions. In practice, industrial facilities often employ both types: fixed-temperature detectors in dusty or hot areas and rate-of-rise units in mechanical or loading zones where rapid fires can occur.

Carbon Monoxide (CO) Detection

Carbon monoxide (CO) detectors add another layer of fire detection, especially in areas with fuel-burning equipment. CO is a colorless, odorless gas produced by incomplete combustion (e.g., from boilers, backup generators, engines). Rising CO levels can indicate a smoldering fire that is not yet producing smoke. For commercial use, electrochemical CO sensors are the standard technology.

An electrochemical CO sensor contains a small gas-permeable chamber with electrodes and an electrolyte. When CO enters the chamber, it undergoes a chemical (redox) reaction at the working electrode, generating an electrical current proportional to the CO concentration. This current is measured and used to trigger an alarm or signal. Electrochemical sensors are highly sensitive to CO, have low power needs and perform accurately over a wide range.

In industrial settings, dedicated CO detectors are placed in boiler rooms, parking garages, loading bays, or near vehicles to alert staff of leaks or incomplete combustion. Today’s combined detectors often merge smoke and CO sensing in one device for convenience and comprehensive coverage. Early CO detection protects workers from poisoning and can even serve as a fire indicator: many fires release CO before thick smoke, so a rising CO reading can prompt an alarm before visibility or heat rise appreciably.

Multi-Sensor Fire Detection Systems

Multi-sensor or multi-criteria detectors combine several sensing elements in one unit. A typical multi-sensor device might include a photoelectric smoke chamber, a heat sensor and a CO sensor, all feeding data to an internal microprocessor. By analyzing these multiple data streams together, the detector can make more informed decisions. For example, a detector might require both smoke and heat signals before alarming, or interpret a combination of mild smoke plus rising CO as a likely smoldering fire. This cross-checking of sensor inputs reduces false alarms: benign conditions (dust, humidity, steam) will not simultaneously trigger all channels like a real fire would.

Multi-sensor detectors are highly useful in sensitive environments such as manufacturing labs or chemical plants, where routine processes might emit smoke or fumes. By recognizing the unique “signature” of a fire event, these systems can alert on real hazards while ignoring normal byproducts of operations. Research shows that multi-sensor fire alarms, often combined with machine-learning classification, significantly improve reliability. In one study, combining smoke, heat and gas sensors and using a binary-classification algorithm let the system distinguish normal fluctuations from dangerous fires, greatly reducing false alarms.

Some of the most advanced units even include flame detectors (UV/IR sensors) or optical light detectors alongside smoke, heat and CO. Others incorporate artificial intelligence to analyze the sensor data patterns over time. These multi-criteria detectors are often addressable (networked) and configurable, letting safety teams tune sensitivity or logic per zone.

Innovations and Trends

Fire detection technology continues to evolve rapidly. Several key trends are shaping modern systems:

- Artificial Intelligence & Machine Learning: New fire detection platforms use AI and ML to continuously analyze sensor data. Instead of fixed logic, these systems learn from historical patterns and incoming signals. For instance, AI algorithms can monitor trends in temperature, smoke density, CO levels, or even equipment vibrations to recognize the precursors of a fire. AI-driven systems can predict where maintenance is needed (e.g., a degrading detector) and even forecast potential fire threats by finding anomalies.

- Wireless and IoT Connectivity: Wireless fire detection components are now common, especially for retrofit in existing buildings. Battery-powered smoke and heat sensors communicate via secure RF links to a control panel or network. This flexibility dramatically reduces installation time and disruption, since there is no need to pull wires through walls or ceilings. Wireless systems are also scalable: sensors can be added or moved easily as the space changes. Modern wireless panels support mesh networking and long battery life (often 5-10 years per device). In parallel, IoT connectivity means detectors can tie into the facility’s IT network.

- Cloud-Based Monitoring and Analytics: Cloud integration is a game-changer for multi-site operations. Instead of fire panels that only sound bells locally, cloud-connected systems upload alarms and sensor data to servers. This enables features like remote diagnostics, historical trending and maintenance reminders. For example, the system can track the number of smoke events or low-battery signals over time. Facility managers can then predict when a detector needs cleaning or replacement. In an emergency, cloud alerts can notify designated staff instantly on their phones, even if they are offsite. Some platforms also share live fire status with local first responders before they arrive.

- Integration with Building Management Systems (BMS): Modern fire detectors often integrate tightly with other building automation systems. When the fire system is connected to the BMS, an alarm can automatically trigger protective actions throughout the facility. For example, the system may shut down fuel pumps, unlock emergency exits, disable elevators (so they stop at the nearest floor), or activate smoke control fans upon an alarm.

- Advanced Sensors: Apart from algorithms and networking, sensor hardware is improving. Some new detectors include optical beam lasers for long-range smoke detection, or infrared cameras that spot fires in large open spaces. Other innovations include fiber-optic linear detectors for ceilings, or flame sensors that detect specific light frequencies from combustion.

Benefits of Advanced Systems

Advanced fire detection brings numerous benefits to facilities:

- Faster and Earlier Detection: By combining multiple sensors and using active sampling, modern systems catch fires in the incubation stage. An aspirating detector can sense a few smoke particles circulating in the air, or a multi-sensor unit can detect the combination of heat and CO before flames erupt.

- Reduced False Alarms: False alarms are costly and dangerous (people can become complacent). Multi-criteria sensing and smart algorithms greatly reduce nuisances. For example, if a brief burst of steam sets off a smoke sensor, an AI-enabled detector would recognize that no heat spike or CO increase followed and may inhibit the alarm. Analytics can also learn typical daily patterns (like a forklift engine turning on at 8 AM) and ignore those. As a result, facilities experience fewer needless evacuations. Studies show that advanced detection systems distinguish normal changes from fire signatures, minimizing false activations.

- Enhanced Integration and Control: Modern fire detection can work with security, access control, HVAC and other building systems for automated response. Centralized monitoring dashboards allow a single operations team to oversee multiple buildings. Managers get unified alerts, maintenance logs and analytics in one place.

- Operational Insights and Maintenance: Advanced systems generate data that improve facility management. Performance dashboards can report on detector health, alarm trends, or system faults. Managers can spot a detector that frequently goes into alarm (indicating a needed check), or verify that a sensor is still functioning.

- Safety and Continuity: Ultimately, smarter fire detection enhances safety and continuity of operations. Quicker detection prevents small incidents from turning into disasters, protecting lives and high-value assets. Businesses save money by avoiding property damage and operational interruption.

Use Cases

Advanced fire detection systems are especially valuable in:

- Warehouses: Large distribution centres and storage warehouses have high ceilings, long aisles and significant air volume. Smoke can dilute under these conditions. Aspirating and beam-type detectors provide broad coverage. Multi-sensor units can ignore dust and pollutants from moving goods.

- Manufacturing Plants: Factories often have machinery, welding and combustible materials. Normal operations may generate heat, steam, or dust that could confuse simple detectors. Advanced detectors with algorithms can tell the difference between normal process outputs and a true fire signature.

- Data Centres and Server Rooms: These facilities house critical electronics that must remain cool and dry. Even a small fire or smoke particle can destroy equipment. Thus, data centres frequently employ aspirating smoke detectors and CO monitoring. The systems are tuned for extreme sensitivity (detecting a few parts per million of smoke).

- High-Risk Environments: Facilities that handle flammable or hazardous materials (chemical plants, oil & gas sites, labs) need the highest level of fire warning. In these settings, advanced multi-sensor detectors (often rated for hazardous locations) and additional gas sensors are used. For instance, a chemical plant might use detectors that sense specific vapors, or a refinery might integrate flame detectors and CO monitors.

Key Considerations for Choosing Technology

When selecting a fire detection solution for a commercial facility, managers should consider:

- Building Size & Layout: The area’s geometry dictates sensor placement. High-ceiling or open-plan areas may require aspirating or beam detectors, whereas smaller offices can use ceiling-mounted point detectors. Large buildings often benefit from an addressable network that pinpoints an alarm to the exact device or room, speeding response. Complex sites (multiple floors, zones) typically need more sophisticated control panels and interconnectinwg sensors.

- Environmental Conditions: Factors like dust, humidity, steam, or chemicals can affect detector choice. For example, dusty manufacturing floors may trigger photoelectric smoke detectors falsely; in such cases heat detectors or aspirating systems with filters are preferable. Areas with a lot of steam (kitchens, laundries) often use heat detectors instead of ionization smoke to avoid nuisance alarms. Corrosive or explosive atmospheres require specially rated sensors (e.g. explosion-proof heat detectors).

- Risk Profile: Evaluate what types of fires are most likely. In a wood-products factory, smoldering fires might predominate, so photoelectric and aspirating detection are wise. In a fuel depot, fast-flame detection (with flame or ionization sensors) is critical. Wherever humans are present, systems must ensure rapid life-safety response. Facilities with fuel-burning engines or confined spaces must include CO sensors as required by code.

- False Alarm Tolerance: Consider the cost of nuisance alarms. Retail stores or hospitals might lose business or panic clients if frequent false alarms occur. In such environments, multi-sensor detectors and AI logic help maintain a low false-alarm rate. In a factory, false alarms disrupt production, so choosing technology that differentiates between a harmless spark or dust cloud and real fire is important.

- Installation and Maintenance: Evaluate wired vs wireless systems. Wireless detectors reduce installation time and are ideal in retrofit situations, but they require battery upkeep. Wired (or addressable) systems offer constant power and may have lower long-term maintenance. Also consider cable routes, panel locations and availability of IT/internet for cloud systems. Ease of access for periodic testing and cleaning is important too. Finally, look for systems with self-diagnostics and remote testing capabilities to simplify upkeep.

- Integration and Scalability: Choose systems that support expansion and integration with other building technologies. This includes compatibility with BMS, security platforms, or emergency notification systems. Scalable addressable loops, IP networking, and standardized protocols (like BACnet or Modbus) allow future growth. Also ensure the system meets relevant fire codes and standards (for example, NFPA 72 or EN 54 requirements).

By weighing these factors; environment, coverage, false alarm impact, budget and regulatory needs, a facility can select the right mix of sensors and features. There is no one-size-fits-all; often the best solution combines multiple technologies.