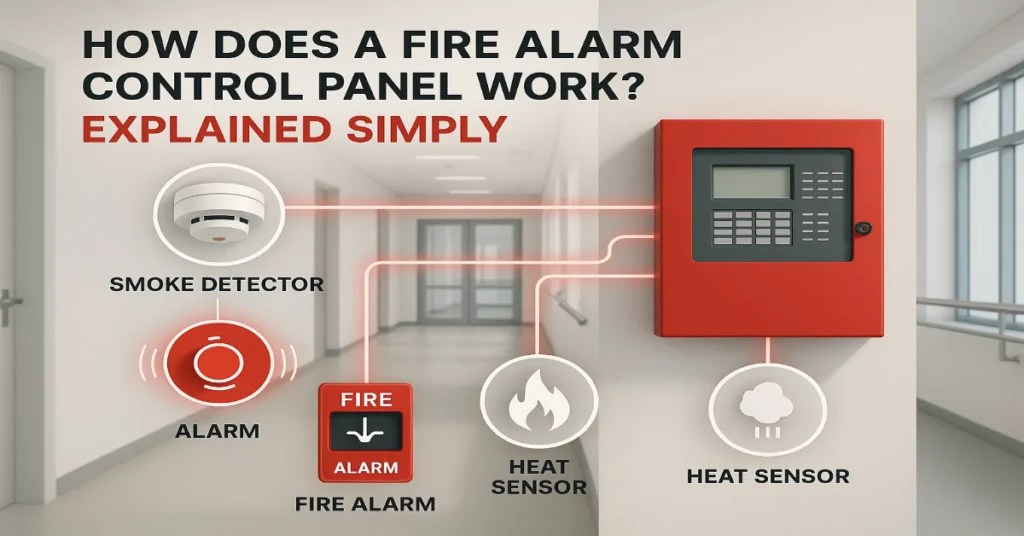

The fire alarm control panel (FACP) is often called the brain of a fire alarm system. It continuously monitors all connected initiating devices (like smoke detectors and manual pull stations) for alarm signals. When a device triggers, the panel processes the signal and decides if it indicates a fire.

If so, the FACP activates all notification appliances (horns, strobes, voice evacuations) to alert occupants. It can also send control signals to shut down HVAC or release suppression systems. Importantly, the panel also supervises system health, checking for open/shorted wiring or device failures and reporting faults or trouble conditions on its display.

In short, the FACP ties together detection, processing and response to alert people and systems of danger and ensuring everything is working properly.

Major Components of a Fire Alarm Control Panel

A modern FACP interconnects several major components and circuits. The major elements include are mentioned below:

- Initiating Devices: These devices detect fires and send signals to the panel. Examples are smoke detectors (ionization or photoelectric) and heat detectors, as well as manual pull stations and sprinkler water-flow switches. Each device has wiring back to the panel so that it can signal when smoke, heat or manual activation occurs.

- Notification Appliances: These devices alert occupants of an alarm. The common appliances are horns, bells, sirens and speakers (audio alarms), plus strobes and LED lights (visual alarms). When the panel goes into alarm mode, it powers these appliances to evacuate people safely.

- Control/Relay Modules: These are output circuits or modules that let the panel interface with other equipment. For example, when an alarm is confirmed, the panel may activate a relay to shut down fans, close fire doors, stop elevators, or pump water for sprinklers. Special control modules may be installed to supervise door-release circuits or valve switches, letting the FACP monitor and control building safety systems.

- Power Supply: The FACP panel needs reliable power. It is connected to building AC mains and contains backup batteries (and a charger) to keep the system running during a power outage. Larger systems may also use a standby generator. Proper design ensures panels can power all detectors and appliances plus keep batteries charged, as required by code.

- Circuits and Cabling: The FACP uses different circuits to manage the system. In conventional panels, each zone or circuit connects groups of detectors and appliances; those are called Initiating Device Circuits (IDCs) and Notification Appliance Circuits (NACs). NACs carry the power/signal to horns and strobes. In addressable panels, all devices share one or more Signalling Line Circuits (SLCs), which the panel polls digitally. Each addressable detector or module has a unique ID, so the panel knows exactly which device sent the signal. (Panels often offer Style Z/A (Class A) or Style Y/B (Class B) wiring for redundancy in NACs and SLCs.) In all cases, wiring must follow local electrical code and NFPA guidelines.

Read Also: Common Fire Alarm Installation Mistakes and How to Avoid Them

FACP Signal Flow: Detection to Alert

When a fire or fault occurs, the fire alarm system follows these steps:

- Detection: An initiating device senses smoke, heat, or is pulled by a person. For example, a smoke detector’s sensor triggers once smoke reaches a threshold. The device then sends an electrical signal down its circuit to the FACP.

- Processing: The panel’s CPU analyses the signal. It determines whether the activation is valid (e.g. not just a minor dust spike) and whether multiple zones or detectors are in alarm (per its programming). If configured, it may require two detectors or verification before sounding.

- Response: If an alarm condition is confirmed, the panel immediately activates outputs. It energizes all programmed NACs so horns and strobes go off throughout the building. It may also trip relays for suppression valves or fire curtains, and it records the event in its internal log. The panel’s display or annunciator will indicate which zone or device went into alarm.

- Communication: In parallel, the FACP notifies others of the event. Local bells/strobes alert occupants and the panel typically signals a 24/7 monitoring station or fire alarm central station. Many modern panels send text/email alerts to facility managers. If the panel is integrated with building management, it can also command HVAC shutdown or release dampers to slow fire spread.

During this whole process, the panel continues to check circuits for trouble conditions (like wiring faults) and distinguishes alarm signals from supervisory signals (e.g. a valve tamper) or trouble signals, presenting any issues on its panel for maintenance.

Types of Fire Alarm Control Panels

Fire alarm systems come in several common types. Each type is designed for different building needs:

- Conventional Panels: These are the traditional systems where each zone has its own dedicated wiring to the panel. A panel light or display indicates which zone is in alarm but cannot identify the exact device. These systems are simpler and cheaper; they work well for small buildings divided into a few zones. However, they require more wiring and labour, and you only know the general area of a fire, not the specific detector. (In practice, a building is divided into zones on the panel, and each zone circuit has multiple detectors or pull stations.)

- Addressable Panels: These are the more advanced panels wire devices in loops, not zones. Each detector or module has a unique address, so when a device activates, the panel pinpoints exactly which one. Addressable systems use digital two-wire loops (SLCs) and send coded messages. This greatly reduces wiring and lets large facilities locate fires quickly. They also simplify maintenance, since each device reports its status (e.g. a “dirty” warning). As one source explains, addressable systems “provide a more precise approach” suitable for larger or complex sites.

- Hybrid Panels: Hybrid (analog/addressable) panels blend both approaches. They allow some conventional zone circuits and some addressable loops. In practice, a hybrid panel might treat a group of devices as a zone but still use addressable protocol to some extent. This offers flexibility, lower cost than fully addressable, but more information than pure conventional. For example, hybrid panels often use conventional hardwired zones but still report extra details digitally.

| Feature | Conventional | Addressable | Hybrid (Mixed) |

| Wiring | Separate wires for each zone | Loop wiring (one or more Signalling Line Circuits) | Mixed zones and loops (vary by design) |

| Device ID | Zone-level only (no ID) | Individual device address (exact location) | Partially zoned; some addressable features |

| Scale | Good for small buildings | Scales to large buildings and campuses | Mid-size systems or retrofit projects |

| Typical Use | Homes, small offices, shops | Offices, schools, hospitals, large campuses | Buildings upgrading or mixing systems |

| Cost/Flexibility | Lower device cost, simpler | Higher device cost, more programming needed | Intermediate cost, configurable |

Read Also: Addressable vs Conventional Fire Alarm Systems: Which Is Right for Your Building?

Residential, Commercial, and Industrial Use

Fire alarm design varies by building type. Residential systems (single-family homes, small apartments) are often very simple. Many homes use self-contained interconnected smoke alarms or a small panel with a few zones. These systems cover key areas (hallways, kitchens) and are designed for ease of use and minimal maintenance.

Modern “smart” home alarms may even connect to mobile apps to alert homeowners remotely, but their code requirements are lighter than for commercial systems.

Commercial buildings (offices, retail stores, schools, hotels) require more robust systems. These use multiple detectors, zones or addressable loops to cover all floors and areas. They often include voice evacuation (speakers with pre-recorded messages), integration with elevators and HVAC and 24/7 professional monitoring.

As one alarm provider notes, commercial panels are “engineered for size” and involve “sophisticated components” compared to residential systems. For example, a large office tower will have an addressable FACP networked across floors, a graphical annunciator showing floor plans and an automatic link to the fire department.

In industrial or campus settings, panels must cover very large or risky spaces. Factories and warehouses use addressable panels with hundreds of devices, often with explosion-proof or specialized detectors in dusty or chemical environments.

Multiple panels may be networked so a central control room sees alarms from all buildings. These systems may also integrate with safety interlocks. For instance, the panel can vent toxic gas or stop machinery if a fire is detected. In all cases, zoning (logical or physical) helps responders quickly narrow down where a fire occurred.

Advanced Features and Integration

Modern fire alarm panels offer advanced capabilities beyond simple alarm/alert. The enhanced features include:

- Zoning and Mapping: Panels can be programmed into multiple zones or building maps. Each zone covers a floor or section, and the panel display shows which zone is in alarm. Addressable panels go further, identifying each device by a unique name or number. This device-level identification greatly speeds response. (Some codes require that zone maps or LEDs be labelled clearly on the panel.)

- Remote Access and Monitoring: Many panels support network connectivity. They can send system status or alarms to a central monitoring station or to smartphone apps. This means a facility manager can get a text alert if an alarm or trouble occurs, even off-site. Remote software may allow authorized users to view panel status or even silence a false alarm remotely, improving convenience and safety.

- Integration with Building Systems: FACPs often tie into other life-safety and control systems. For example, when an alarm goes off the panel can command the HVAC system to shut down (to prevent smoke spread) and trigger fire doors to close. It may interface with the elevator control to recall elevators to the ground floor.

Sprinkler systems integrate via water-flow switches or supervisory valves; when sprinklers activate, the panel creates an alarm if it hasn’t already. Modern building management systems may use protocols like BACnet or Ethernet to link fire panels with access control and security, allowing unified emergency coordination (for instance, unlocking doors for firefighters while locking out an intruder alarm).

- Advanced Detection Technology: New panels can work with smart detectors. Multi-criteria sensors combine smoke, heat and CO readings to improve accuracy. Some systems even use video smoke detection (cameras looking for visible smoke) or aspirating detectors (air sampling). These improve early detection and reduce false alarms. The panel’s software can apply analytics. For example, if several nearby sensors trip in a pattern, the system can assess severity or pre-alarm stages before full evacuation.

Inspection, Testing and Code Compliance

Fire alarm systems are heavily regulated. In the U.S., NFPA 72 (the National Fire Alarm and Signalling Code) requires regular inspections, tests and maintenance of all fire alarm equipment.

Similarly, the International Fire Code and local building codes impose strict standards. European standards (EN 54 series) define performance criteria for control panels and power supplies. These rules specify how often devices must be tested (e.g. monthly smoke detector tests, annual full system tests) and require detailed documentation of all work.

Routine inspection and maintenance are essential best practices. Certified technicians should conduct scheduled tests such as activate detectors or pull stations, verify zones and outputs and check the panel’s trouble indicators. Backup batteries must be load-tested and replaced per manufacturer specifications.

Accurate record-keeping is itself a code requirement like detailed logs of every inspection, test and repair must be maintained. Building managers should address any non-compliance immediately. Regular preventive maintenance, cleaning dust, tightening connections, updating software keeps the system reliable.

In summary, adherence to NFPA 72 (or equivalent ISO/EN standards) and disciplined maintenance (as recommended by experts) is essential for effective fire safety.

Common Issues and Troubleshooting

Even well-designed fire systems can have faults. Fire safety experts should also know these common problems and fixes such as:

- False Alarms: These are one of the most frequent headaches. False triggers often come from dust, steam, insects or cooking fumes setting off smoke detectors. Electrical interference or power surges can also sound alarms incorrectly. Regular maintenance helps; for example, cleaning detectors and relocating them away from high-humidity areas can reduce spurious alarms.

- Power and Wiring Issues: A lost power supply or wiring fault can prevent alarms or cause trouble signals. If a panel shows a power or trouble indication, first check that AC power is present and backup batteries are charged. Loose or corroded wiring connections in initiating circuits or NACs can disrupt signalling. Troubleshooting steps include inspecting cables, tightening terminals and ensuring proper circuit supervision.

- Faulty Devices: Sensors or pull stations that become unresponsive can go unnoticed until a fire. Regular testing (monthly or quarterly) should activate each device. If a detector fails to alarm or signals intermittently, it may need cleaning, recalibration or replacement. Addressable panels help here by reporting specific device faults on the panel display.

- Stuck Notification Appliances: Occasionally a horn or strobe may not sound due to a disconnected wire or defective unit. Regular sounder tests can catch this early. If an entire NAC isn’t powering appliances, check for a short or overload on that circuit and verify the panel’s amplifier and fuses.

In general, when a panel shows an alarm or trouble, technicians should read the display or annunciator for codes. Most modern panels log events and error codes that aid diagnosis. Often, a system reset, and retest is the first troubleshooting step. Clear labelling of zones and device names (as required by code) greatly speeds fault location. Keeping spare batteries and common replacement parts on hand also reduces downtime.

Best Practices and Future Trends

To ensure lasting reliability, follow these best practices like use qualified, licensed technicians for design and maintenance, adhere strictly to manufacturers’ specifications and keep detailed records of all service. Training building staff on alarm procedures and having clear evacuation plans enhance safety.

Building-wide integration will continue growing. Panels are increasingly tied into full building management (HVAC, lighting, access control), creating unified emergency response networks. Voice evacuation and mass-notification capabilities (text alerts, public-address messaging for weather or active threats) are also being added.

Longer-lasting power solutions, like solar panels or super-capacitors and wireless mesh detectors are also coming soon. All these trends point to smarter, more reliable fire safety monitoring that protects life and property more effectively.

Read Also: Best Practices for Fire Alarm System Maintenance in Commercial Buildings